IBM’s Dr. Ben Amaba, a member of PPI’s Industry Council, and Ed Pound, Director, Production System Optimization at Strategic Project Solutions recently described an Operations Science perspective of how a blockchain implemented in the supply chain of capital projects can improve project execution performance.

1) Blockchain creates a ledger, a system of record, that is shared among participants in a transaction. The participants’ view of data can be filtered as needed. For instance, all contractors on a module do not see how much each is paid. However, they may be allowed to see when their work is scheduled, when it is completed and the history of all the material in the module from fab to installation.

2) Provenance of the information is clear and transparent. Everyone with permission sees the same information at the same time. If a project owner wants to see information about seamless drilling pipe in a well such as:

the blockchain transaction contains that information. The project owner does not have to go to the driller who then may have to go to the pipe distributor who then has to go to the pipe manufacturer who then has to contact the casting foundry. The ledger data is updated automatically as changes are made to the pipe’s record.

3) All transactions are immutable. In other words, once a transaction is entered into the ledger it is final and unchangeable. Of course, this is backed up with powerful cryptography to ensure that all transactions in the ledger are secure. Both the blockchain technology, infrastructure security, and strong cryptography provide very high levels of security

and privacy.

Figure 1 illustrates a comparison between the information flows in a supply chain of a capital project changes with the implementation of a blockchain. The illustration was originally shown in June Digital Manufacturing and Design Innovation Institute’s (“DMDII”) supply chain conference in Chicago—

A current state view of a capital project’s supply chain is one of widely-distributed networks of information, sequential and sluggish in terms of response time, as shown on the left hand side of Figure 1. With the implementation of a blockchain, the information flows transition to a compact, parallel and highly responsive single network of information.

An operations science view of that transformation provides quick insight to the foundation of blockchain benefits.

The key here is to view information requests as work-in-process (WIP). Once that perspective is taken the benefits become obvious.

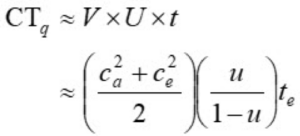

For basic operations science insight, we use the VUT equation:

Cycle time in queue (CTq) is affected by:

1) V – variability in the process

2) U – utilization of resources in the process

3) te – the underlying processing time of information while at resources in the process.

For more information on the science behind this relationship, see Factory Physics for Managers, pp 72 – 80.

As shown in the capital projects illustrated in Figure 1, blockchain technology blows

up the extended, intertwined networks of information processing that is typical in many supply chains.

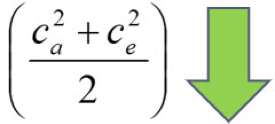

1) Information is all in one place so variability (the “V” term) is reduced through standardization of information.

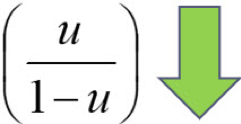

2) Requests do not have to flow back and forth up and down a supply chain which reduces overall information request WIP and thereby reduces overall utilization (the “U” term) of resources, e.g. planners, accountants, engineers and project managers, in project operations. This has a huge impact on reducing queue time.

3) Finally, with information for a part all in one place and easily accessible, the time to complete a request (te, the “t” term) is greatly reduced.

By Little’s Law, WIP is visible cycle time. All of these benefits accumulate to massively reduce the information request WIP in a project. So, the tasks and products associated with the information requests get completed much more quickly. This is basic operations science and it quite often leads to higher revenue and lower costs.

Information requests are usually tied to the completion rate of tasks in a project. The end products and services of each echelon of a project generate revenue for that echelon. Have you ever had a fabrication task, rebar cages for example, or project installation task, wiring a room for example, wait on resolution of paperwork?… It’s pretty common. Implementing blockchain technology reduces information request WIP which reduces the time required to process information which reduces operations costs.

Shorter processing time at a resource increases resource capacity which means more throughput (revenue) for less cost. For capital projects, the potential effect is to reduce waste of capacity of resources and WIP, shorten response time and complete projects faster for

less cost.

A caveat though for capital projects and all blockchain applications—in general, Engineering, Procurement and Construction (“EPC”) project managers and capital project owners are poorly informed on operations science as it applies to project delivery.

Dr. Ben Amaba is responsible for managing IBM’s innovation process that identifies strategies, business opportunities and new technologies and then develops new capabilities and architectures with partners, academics, new business models and new industry structures to serve the industrial market with the IBM Watson and Cloud platform. He manages the process of innovation and change management for customers to recognize and benefit from disruptive technologies in artificial intelligence, data sciences, cloud platforms, Internet of Things (IoT), additive manufacturing and robotic process automation (RPA).

Ed Pound is Director, Production System Optimization at Strategic Project Solutions. Ed has worked with major international companies such as Intel, 3M, Baxter Healthcare, Chevron and Whirlpool providing education and consulting in the practical Operations Science of Project Production Management concepts. Ed is lead author, along with Dr. Mark Spearman and Jeff Bell, of McGraw-Hill’s lead business title Factory Physics for Managers.