Construction projects frequently begin under conditions of high uncertainty, leading to complex situations in which both the final product and the execution process are not fully defined. Drawing on the Stacey Matrix [1], agile methods such as the Last Planner® System (LPS) [2] or Design Thinking [3] prove effective in initially navigating complexity through the integration of transparency and preventing the slide into chaos. As a project’s product and process become clearer, however, the approach can transition from complex to more structured domains, allowing for the application of lean production principles akin to those in the manufacturing industry. This paper examines the conceptual and practical underpinnings of such a shift, focusing on the integration of takt planning and takt control to streamline industrialized construction processes. A case study from a construction company (weisenburger bau GmbH), which has executed over 250 projects with the takt production system, including 100 recent full digital projects with comprehensive data on 220,000 work packages and more than one million work steps, demonstrates great data in flow efficiency and project durations. Based on these findings, recommendations and lessons learned are offered to guide practitioners in adopting a balanced approach, leveraging both agile methods for early uncertainty management and lean methodologies for more predictable, efficient production phases. The research data is limited to multi-dwelling and residential housing under German procurement conditions. Furthermore, the testing should involve higher-complexity asset classes in the future.

Keywords: Production Engineering, System Design, Takt planning

The construction industry worldwide faces a unique set of challenges due to the inherent complexity of building projects. These projects involve a multitude of actors, trades, technologies, and always changing requirements. From the very beginning, especially during the early planning phases, the author often observed that the projects are neither fully clarified nor adequately defined. This uncertainty extends to both the final product (the result) and the production process (the path to the outcome), which remain ambiguous for an extended period. Only as the project progresses do these aspects start to become clearer, at a stage where resolving ambiguities proves to be difficult or even too late.

This situation is a significant contributor to the inefficiencies observed in large-scale international projects and across the broader market. Many projects struggle to define the desired product and the production process early enough, leading to challenges such as scope creep, misalignment of goals, and inefficiencies in resource allocation. These issues are especially pronounced when projects rely on traditional methods of planning, where the result and the pathway to achieving it are not sufficiently explored during the early stages. This is a problem, as methods like the Critical Path Method require clearly defined and predetermined conditions to be applicable in the first place.

The results from large international projects show a clear trend: the earlier the project uncertainties are addressed, the more likely the project will stay on track, meet deadlines, and adhere to budget constraints [4]. Conversely, delaying the clarification of the product and process often results in costly adjustments and delays, leading to reduced efficiency and overall project failure. [5]

The construction industry’s failure to address these uncertainties early on not only impacts project outcomes but also poses a risk to the industry’s reputation for reliability. Therefore, addressing these issues in the early phases of the project lifecycle is crucial to mitigating risks and ensuring successful project delivery. It is in this context that modern approaches to project management, such as Lean Construction and advanced digital tools, are becoming increasingly important. These methodologies aim to bring clarity and standards to the planning phases by focusing on the reduction of waste, the improvement of communication, and the timely identification of key project details, thus ensuring that the product and production process are clearly defined from the outset.

Complexity and Chaos: Agile and Creative Methods as a Solution Approach

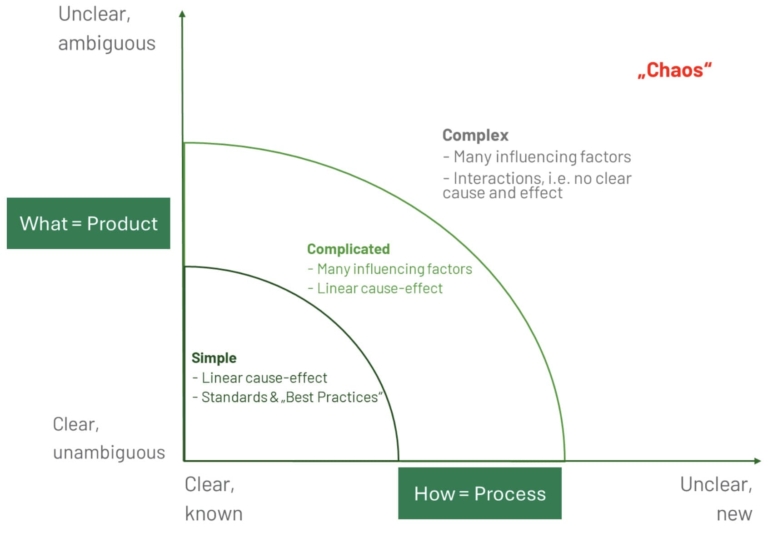

If clarification isn’t achieved early on within the project, a very high level of complexity arises. If the product and process aren’t sufficiently clarified over the course of the project, there’s a risk of a slide into chaos, resulting in the results described above. A diagram based on the Stacy Matrix [1] can be used to illustrate this relationship.

Figure 1: Stacey Matrix [1]

The horizontal axis of the matrix reflects the clarity of the process, the “how” of project execution. A company that has repeatedly built single-family homes, for instance, operates within a familiar process landscape. But if that same company were to take on a school construction project, many of the routines and process knowledge from previous projects might no longer apply. This lack of transferable experience introduces process-related uncertainty and shifts the project into a less predictable zone. Another influencing factor is the constant change in resources, which leads to a regular interruption in the flow of information.

The matrix itself is divided into different zones depending on the levels of product and process clarity. When both are highly clear, work can be structured and executed with relative ease. A simple work plan often suffices to achieve the desired results in such environments. However, as uncertainty increases, either due to unclear goals, unpredictable environments, or unfamiliar processes, the project moves into a complicated, and then into a complex domain. In these zones, traditional linear planning becomes less effective, as not all variables can be anticipated or controlled, and the influencing factors increase. Instead, adaptive, and agile methods are necessary. These approaches enable teams to respond flexibly and contextually to emerging challenges and changing requirements. If both clarity of product and process are lacking, the situation becomes chaotic, a state in which control is lost entirely, and urgent, improvised action is needed just to regain stability.

In construction projects, we frequently encounter phases characterized by high complexity. In such situations, traditional planning and control methods often reach their limits. Agile methodologies and creative techniques, such as Design Thinking and the Last Planner® System, are effective to manage uncertainty and rapidly establish transparency. The LPS, in particular, focuses on enhancing the reliability of planning by actively involving those responsible for implementation, the “last planners”, and developing a realistic schedule through a collaborative and iterative process. [2]

Drawing on the author’s practical experience, these approaches prove especially valuable in the early stages of a project. They support a deeper understanding of the construction scope, help clarify requirements, and progressively reduce uncertainty. Agile principles, including short feedback loops, continuous adaptation, and close team coordination, play a crucial role in transforming complexity into clarity and enabling more responsive and effective project delivery.

Transition To Less Complexity: Lean Production And Standards As An Opportunity

According to the Stacey Matrix, once both the product and the process achieve sufficient clarity, projects transition from the realm of complexity into the complicated or even simple domain. However, based on the author’s observations, this shift is rarely seen in the construction industry. Based on the authors experience and observations, mist companies don’t even strive for the reduction of the complexity. Furthermore, they accept the current situation and try to optimize it instead of changing the business model and conditions. In contrast to other industries, where standardization and repeatability are often the norm, construction is typically characterized by the creation of seemingly unique, one-off projects.

Industries such as automotive manufacturing or electronics often exemplify this move toward simplicity, with efficiency and predictability as core principles. These values, however, are not always compatible with the construction industry’s reality. Exceptions do exist, for example, modular builders, prefabricated home manufacturers, or companies that specialize in highly standardized products (e.g. Goldbeck GmbH, Cree buildings or Blox Built with its parking garages). These examples highlight the potential for simplification, but they remain outliers that underscore the norm of variability and complexity in construction. This transition is only possible if you standardize your product and work on process optimization.

Nevertheless, if clarity can be achieved, pushing a project into the “simple” zone, it logically follows that processes become more streamlined, costs decrease, and quality improves. In such scenarios, topics like standardization and lean production principles offer significant support and added value.

When applied to the construction sector, this evolution represents a shift from agile or Last Planner® System (LPS) practices toward more structured and disciplined process models. A compelling example of such a structured approach is takt planning and takt control. Borrowed from industrial flow production, this method divides a construction project into recurring “takts”, defined as specific sections of a building and time intervals during which predetermined work packages are executed in a consistent sequence. The result is a standardized, rhythm-based construction process that fosters high levels of planning accuracy and process stability. This again leads to the next step: Within a project, the planner and workers onsite are forced to work in a repetitive way and this leads on the other hand to more process optimization, efficiency and to the next process evolution level.

Takt Planning And Takt Control: Accelerating Industrialized Construction Processes

At this stage, agile approaches do not disappear entirely but recede into the background, as the project becomes increasingly predictable and manageable. This is where takt planning and takt control can unleash their full potential. By clearly structuring work steps, establishing fixed time intervals, and defining execution sequences in advance, a truly industrialized approach to construction becomes possible.

In flow production, takt is defined as the ratio of allowable time to total output, representing the interval between consecutive outputs. To ensure smooth production, each operation must be completed within this takt time, including allowances for product variation. Consequently, maintaining continuous product flow typically takes priority over maximizing capacity utilization, as disruptions in flow are linked to project inefficiencies, delays, and increased costs. [6, 7] This prioritization presents a significant challenge in construction production flow. Although capacity utilization is secondary to overall production continuity, it remains an essential factor.

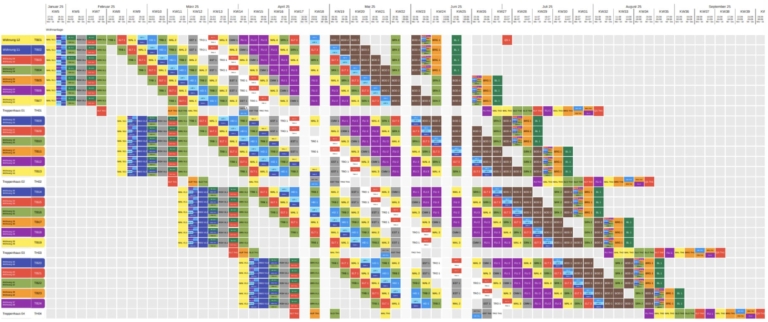

One common approach to optimize capacity utilization is to structure work packages to consistently meet takt time, though this may introduce gaps in the flow, as illustrated by blocks at the beginning and end of the schedule (see Figure 2). Poor utilization adversely impacts economic efficiency, underscoring the importance of effective resource planning. The primary lever to enhance utilization quickly is adjusting manpower allocation. However, at more advanced stages of development, modifications in product design aligned with production requirements become necessary. Further strategies, such as employing multi-skilled workers or flexible “jumpers,” represent advanced techniques to optimize resource utilization.

An example of a real takt schedule is illustrated in the figure 2. Within this production system, a two-day takt time serves as the standard temporal unit. Correspondingly, the standard spatial unit is defined as two flats, with an approximate combined area of 150 m². The workflow is visualized using colored boxes, where each box represents a clearly defined work package, and the color indicates the corresponding trade. These distinct, color-coded processes move rhythmically through the building, making it easy to identify which activity is scheduled in which area at each takt time. This visual structure supports transparent coordination and highlights the synchronized flow of work across the project. [8, 9]

Figure 2: Example of a takt schedule

This not only shortens lead times but also significantly improves resource efficiency. The growing role of digitalization further enhances these processes, enabling continuous performance monitoring, automated evaluations, and real-time data analysis. [10, 11]

One company that has already embraced this approach extensively is weisenburger bau GmbH, a family-owned middle size General Construction Company from South Germany. To date, the company has implemented more than 250 turnkey residential construction projects using this method. In recent years, weisenburger bau has transitioned to a fully digital workflow, enabling the structured collection and analysis of large volumes of data. This digital foundation supports both process optimization and data-driven decision-making across projects. Weisenburger bau serves as a single-case study of residential housing. It’s an informative, but bounded prototype.

Process: From Project Kick-Off to Takt Planning

For several years, weisenburger has used takt planning as a central tool for structuring construction processes. As early as the initial project phases, construction workflows are broken down into recurring, logically sequenced steps, so-called takts. These takts are systematically defined based on planned construction sections, the project type, and the available resources. Over the years weisenburger has created over 30 standardized sequences for different project types with defined quality steps and work content. The predefined sequences work for almost 95% of new incoming projects, sometimes only smaller project specific changes are necessary. The standardized sequences are always under a continues improvement process from project to project. This the backbone of the production system and the first standardization step. The aim is to establish a stable, consistent production rhythm across the entire project.

Planning is carried out in close collaboration between site management, specialist planners, and subcontractors to ensure technical feasibility and practical relevance. Weisenburger places particular emphasis on integrating the takt logic early into the overall project schedule to minimize later adjustments and provide a reliable foundation for execution.

Implementation: From Planning To Takt Control and Visual Management

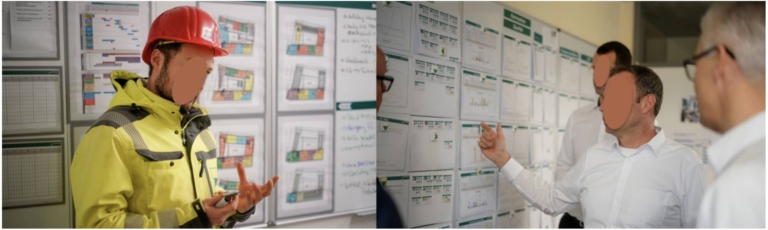

During the execution phase, takt control is used at weisenburger to consistently implement the planned structure on site. Each takt is assigned a clearly defined timeframe, a specific scope of work, and a responsible trade. Daily takt meetings and on-site visual management (see figure 3) ensure that deviations are identified early and corrective actions can be taken promptly.

Figure 3: Shopfloor management and Visual Management at weisenburger bau GmbH

Takt control not only facilitates adherence to the schedule but also strengthens coordination among trades and promotes a high degree of reliability in project delivery. The result is a continuous, rhythm-based production flow; fully aligned with the principles of industrialized construction. If something goes wrong, adjustments are done live.

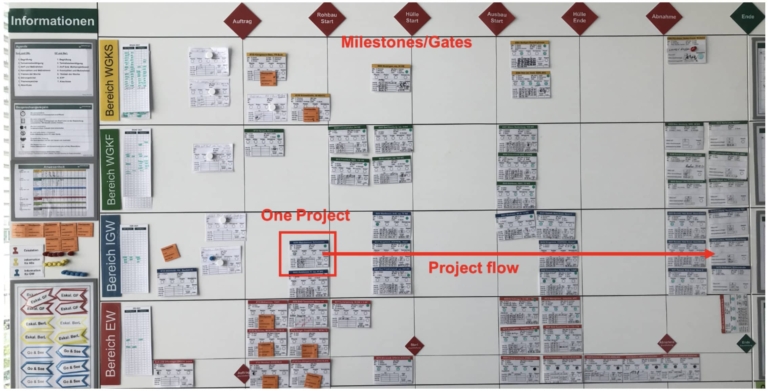

From A Single Project To A Production System

Over 12 years ago, weisenburger began with individual pilot projects to explore takt-based construction. As the approach matured and proved effective, it was steadily scaled from one project to over hundred. Today, every project is delivered within a unified takt system, transforming each construction site into a component of a broader company-wide production system. This shift is visually reinforced at the executive level: a physical summary board (see figure 4) illustrates the flow of projects through the construction system, embodying the principles of visual management and illustrates systematic process control. This step was only possible because all projects follow uniform rules, are divided into similar work packages and are based on the same process sequences.

Figure 4: Multi-project flow view at the highest company level

Digital Support for Takt Projects

Takt planning and takt control as well as the overall system is supported by digital tools such as real-time data analysis and progress tracking, the construction team can act transparently and responsively. This leads us to a wealth of data is available from the last 100 digitally executed projects, encompassing approximately 220,000 work packages and over one million individual work steps. This robust data foundation enables analytical comparisons of key performance indicators such as flow efficiency [12, 13] and lead times. It allows for an in-depth evaluation of how systematic takt planning and takt control influence construction duration, quality, and resource utilization across various project types.

Initial insights from these analyses indicate that industrialized construction processes have a clear positive impact on schedule adherence and process reliability. The construction time is reduced up to 50%. Through standardized takt sequences, strict project controls, and proactive planning, disruptions are minimized, and rework is significantly reduced. At the same time, transparency between project stakeholders increases, fostering seamless collaboration between planning and execution.

Added Value Through Data

The construction company manages between 50 and 80 concurrent projects (see figure 4) of varying scale and complexity, ranging from small developments with two semi-detached houses to large-scale multi-apartment buildings comprising up to 100 units and project volumes of over €20 million. Despite this heterogeneity, the use of standardized and takt-based data structures enables a system-wide aggregation, evaluation, and visualization of project data.

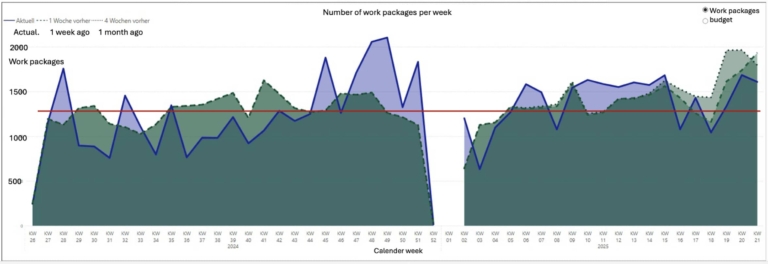

The figure 5 illustrates a multi-project view, displaying both planned and actual work packages per week. The data reveals a consistent and stable execution rate of approximately 1,000 to 1,500 work packages per week across all active projects. This high-resolution data stream forms the backbone of a data-driven construction management system.

Figure 5: Data warehouse multi project statistic

Figure 5 represents the status quo in the transformation of the company. There has been a significant change in focusing on and optimizing a single project to a wider production system approach, where standardized work packages are planned, controlled, and executed to finish single projects as a part of the system. This mindset shift leads to qualified data. The availability of such structured and harmonized process data unlocks substantial added value in several dimensions. First, it improves decision-making in the tendering and preconstruction phases by providing historical benchmarks and empirical construction durations. Second, it enables predictive forecasting regarding project timelines, resource demands, and site performance. Third, it supports detailed reporting at both the project and subcontractor level. An example of a subcontractor performance report is illustrated in figure 6.

Crucially, every work package is digitally linked to the responsible trade partner and the corresponding cost structure. As a result, core management functions such as Earned Value Management (EVM) and financial reporting become largely automated by products of the ongoing operational data flow. In the following figure you can see the subcontractor performance chart visualized in a BI Tool.

Figure 6: Subcontractor performance charts built in Microsoft Power BI from live project data

Over the past few years, the company has undergone a profound transformation. Key takeaways from this journey include the following:

The purpose of using the Stacey Matrix in this study is to provide a clear framework illustrating how weisenburger bau GmbH applies different management approaches depending on project types and situational contexts. It effectively captures the rationale behind weisenburger’s strategy of moving projects from complex or uncertain domains toward simpler, more predictable states where standardized, takt-based processes become feasible.

However, it is crucial to acknowledge that not every project or situation reaches this optimal state of simplicity. While agile methodologies are effective in managing initial uncertainties regarding project requirements, takt planning primarily targets the reduction of process variability. The transition from agile to more stable approaches lack clearly defined indicators, though the general progression from uncertainty to clarity is evident across projects.

Importantly, weisenburger’s proactive drive toward the “easy” domain of the Stacey Matrix is atypical within the broader construction industry. Traditional construction companies often accept complexity as an inherent characteristic of their work, lacking either the motivation or capability to transition toward standardized, simplified processes. Conversely, companies increasingly adopting modular or industrialized construction methods exemplify an extreme commitment to prefabrication and standardization, representing a significant departure from conventional industry practices, because they are not accepting complexity and uncertainty within their projects and production.

This case study is limited by its focus on a single company operating in Germany and within the residential sector. While based on 50–80 concurrent projects, findings may not be transferable to more complex asset classes like hospitals, nuclear plants, or infrastructure projects. The mature digital environment also limits comparability with less digitized contexts.

Future research should include comparative studies across different companies, sectors, and countries. Special focus should be given to high-variability projects and simulations of takt planning under uncertain conditions, as well as financial viability under diverse contractual frameworks.

Construction projects often begin in a state of uncertainty. In these early stages, agile and creative methods are crucial to mastering complexity and avoiding chaos. As product and process clarity increases, lean production methods and takt-based scheduling become valuable tools for industrializing construction workflows. At this point, it should be noted that the author does not want to be misunderstood. The Stacey Matrix is a framework, and the precise definition of the methods must be viewed situationally and relative to the situation and cannot be considered absolute. Nor do more stable frameworks exclude agile methods, and vice versa.

The case of weisenburger bau demonstrates impressively that with consistent digitalization and standardized processes, data is available, and this leads to significant improvements in time, cost, and quality.

The insights shared here lead to a clear recommendation: start with agile methods in the early project phases to navigate uncertainty, and transition toward lean tools and takt-based processes as clarity improves. A strong focus on data and performance metrics, coupled with close collaboration across all project participants, completes this success model.

The lessons learned over recent years show that a targeted combination of these approaches, from agile units to industrial-scale execution on-site, enables substantial process optimization. Those who begin the journey toward industrialization and digitalization early can gain a decisive competitive advantage in today’s highly dynamic market environment.

[1] Stacey RD. Strategic management and organisational dynamics: the challenge of complexity. 3rd ed. Harlow: Prentice Hall, 2002.

[2] Glenn Ballard (2000). The Last Planner System of Production Control, Berkeley University, Dissertation LPS

[3] Liedtka, J. (2015). Perspective: Linking Design Thinking with Innovation Outcomes through Cognitive Bias Reduction. Journal of Product Innovation Management, 32(6), 925-938.

[4] Gładysz, Barbara. (2022). Sustainable Metrics in Project Financial Risk Management. Sustainability. 14. 14247. 10.3390/su142114247

[5] Flyvbjerg, B. (2023). How Big Things Get Done: The Surprising Factors Behind Every Successful Project, from Home Renovations to Space Exploration. Crown Publishing.

[6] Project Management Institute (2021). Pulse of the Profession® 2021: Beyond Agility. PMI. https://www.pmi.org/learning/thought-leadership/pulse/pulse-of-the-profession-2021 (13. Juli 2025)

[7] Hopp, W. J., & Spearman, M. L. (2008). Factory Physics: Foundations of Manufacturing Management (3rd ed.). McGraw-Hill/Irwin, New York. ISBN: 978-0072824032.

[8] Frandson, A., Berghede, K. & Tommelein, I. D.. (2013). Takt Time Planning for Construction of Exterior Cladding. In Formoso, C. T., & Tzortzopoulos, P. (Eds.), 21th Annual Conference of the International Group for Lean Construction (pp. 527–536).

[9] Haghsheno, S., Binninger, M., Dlouhy, J. & Sterlike, S.. (2016). History and Theoretical Foundations of Takt Planning and Takt Control. 24th Annual Conference of the International Group for Lean Construction (pp. 53–62).

[10] Binninger, M., Dlouhy, J., Müller, M., Schattmann, M. & Haghsheno, S.. (2018). Short Takt Time in Construction – a Practical Study. 26th Annual Conference of the International Group for Lean Construction (pp. 1133–1143). https://doi.org/10.24928/2018/0472

[11] Dlouhy, J., Grobler, W., Binninger, M. & Haghshen, S. (2017). Lean Equipment Installation – Potentials of Using Takt Planning. 25th Annual Conference of the International Group for Lean Construction (pp. 721–728). https://doi.org/10.24928/2017/0091

[12] Binninger, M., Dlouhy, J. & Haghsheno, S. (2019). Flow in Takted Projects – A Practical Analysis of Flow and Resource Efficiency. Proc. 27th Annual Conference of the International Group for Lean Construction (IGLC) (pp. 1271–1282). https://doi.org/10.24928/2019/0228

[13] Modig, Niklas; Åhlström, Pär (2015), This is Lean: Resolving the Efficiency Paradox.

Stockholm: Rheologica Publishing. — ISBN: 978-91-87791-09-3