Project Production Management (PPM) is sometimes described as “applying manufacturing techniques to projects,” implying that PPM only applies to scenarios with highly repeatable and predictable conditions. Consequently, many experienced project professionals mistakenly believe that PPM denotes a “manufacturing approach” to capital projects. To the contrary, evidence shows that PPM applies to the execution and delivery of all projects, large or small, customized or standardized, and improves upon prior conventional project management practices. We further demonstrate that, depending upon the complexity of scope, implementation of PPM on “one-off” projects is even more critical to achieving stated objectives.

PPM is based on operations sciences, a well-established field of engineering, as the foundation of production systems. All manufacturing systems are production systems; however, not all production systems are manufacturing systems. A deeper analysis of the work activities in projects shows different types of production systems embedded within a single project. Describing project work activities as a set of interconnected production systems makes them amenable to the modeling and analysis tools of PPM. These tools can be used to predict the limits of project execution and where best to manage variability through the strategic allocation of buffers such as capacity, inventory and time. Select case examples are included to illustrate these concepts.

Keywords: Production System; Operations Research; Job Shop, Line Flow; Product-Process Matrix

A question frequently posed by participants in PPI Seminars is: “My project is a one-off, there is no repeatability, so how can a discipline developed for manufacturing, where processes and work activities take place in an environment that is more constrained and predictable, where scopes are generally highly repeatable with small tolerances, apply to projects with unique scope and where work activities must be tailored to circumstances with considerable uncertainty and variability?”

The often-cited analogy with manufacturing evokes a picture of highly repeatable tasks with well-defined scope that are consistent across many projects, not merely for the current project under execution. It is on this basis that even some seasoned project professionals are confused by the reality that Project Production Management is, in fact, applicable to the execution and delivery of one-off or unique projects.

This article seeks to dispel such misconceptions, explaining the rationale behind the Institute’s position that Project Production Management is the next practice for executing today’s projects being undertaken across different industries. We first give a qualitative discussion highlighting the assumptions of repeatability that are inherent in today’s conventional project management practices. This observation motivates the search for a more systematic framework to understand what work activities in a project might be amenable to analysis and optimization methods used in other settings. That framework is operations research and management [4 – 8] – its application to develop a taxonomy of the different types of production systems has been explained in prior literature [2 – 4], and is reviewed here. Manufacturing systems are examples of a type of production system, but not all production systems are manufacturing systems. The same equations and science apply to different types of production systems; the consequences of those equations can look very different from production system to production system, but the underlying principles remain the same. One conclusion from this analysis is that Project Production Management should not be simply viewed as the application of line flow [4], known in high volume manufacturing, to projects. That is far too simplistic, as Project Production Management is far richer than that, whereby operations research dictates that different types of production systems will have different embodiments to optimize key project parameters such as throughput, work in process (WIP) and cycle time.

We use the taxonomy of production systems to then perform a deeper analysis of the work activities in capital projects, showing that a typical project is usually a combination of different types of production systems embedded within. Applying the principles of operations management allows one to optimize the critical parameters describing overall project performance. We illustrate this with two examples, the first being a capital project from the oil & gas industry, and the second being a civilian infrastructure project. We close with identifying some gaps in today’s execution of project delivery that the Institute will address in a future paper providing more detail on identifying and understanding the different types of production systems in a project.

It is certainly true that many projects, and certainly most large capital projects, can be unique in scope and comprise many highly-customized elements. We argue in this section that when project scope and work activities are examined at a sufficiently granular level of detail, it is possible to find significant repeatability: repeatability in knowledge, repeatability in work execution tasks and repeatability in product components. Once that repeatability is identified, it is amenable to analysis and optimization using the mathematical tools of operations research, to understand how to identify standardized knowledge and standardized processes. One concludes that custom products or projects of unique scope can be designed from standardized knowledge and built using standardized processes.

While every tool and technique developed and applied in manufacturing over the last century is certainly not directly applicable to projects, manufacturing and projects have at least one thing in common: in nearly every project, one is producing something, just as in manufacturing. And so, infrastructure projects are configured to have finished infrastructure at their completion: onshore oil & gas field development projects aim to deliver producing oilfields with producing wells, drilled, completed and tied in to pipeline infrastructure, and so forth.

In a qualitative sense, projects are production systems because they configure resources to work on inputs to “make or produce something.” The etymology of the word “produce” [1] is “to make something,” derived from the Latin word produco, or “to bring forth.” Everything occurring to achieve that production objective is what comprises the system. The Latin word produco, derived from the root Duco, “to lead,” implies control and clarity of vision. Whereas, the etymology of the word “project” [1] is from the Latin pro, or “forward,” and ject or “throw,” which evolved in English to mean “a planned endeavor.”

The existence of technical disciplines, as well as crafts and trades, is evidence that projects also have knowledge content and work that has inherent repeatability. In fact, technical disciplines, crafts and trades, codify the knowledge encountered and applied in projects for re-use. For instance, in oil and gas projects, such as LNG projects, if one asks experienced professionals how much of the actual content in a new LNG plant is entirely new, never used before, the answer typically ranges from 10-15%. Similarly, in civilian infrastructure, while each piece of infrastructure can indeed be unique, the fact is, most of the elements that might go into a unique piece of construction have been used in prior projects. This qualitative observation is by itself not surprising, but the fact that conventional project activities use functional disciplines such as engineering, design, project scheduling and forecasting as well as skilled labor, crafts and trades, implies there are bodies of knowledge that can be used and re-used in executing projects (i.e., there is something repeatable being employed to produce an item of unique scope). Said differently, the Product is unique, whereas most of the Process is repeatable, and elements of the Product are repeatable, as well as the knowledge required to design and create the Product. This observation is crucial – most people when they think about “standardization,” tend to think about “standard products.” The point made here is that “standard processes” can be just as important, if not more important, in establishing repeatability that can be leveraged in the execution of those processes.

The preceding discussion provided qualitative arguments on projects as production systems insofar as projects “produce something.” It also identified the repeatability of certain types of knowledge required and applied in project execution, thus pointing to the existence of technical and craft disciplines as evidence of that repeatability. However, qualitative observations of parallels between projects and production systems are not sufficient to understand how to analyze and optimize project execution. In this section, we review the prior literature that has explored the application of the scientific methods of operations research and operations management to production systems of various types.

When people hear “production system,” they generally think of mass manufacturing. While all mass manufacturing systems are production systems, not all production systems are mass manufacturing systems. What do we mean by this? In the world of operations, it is well established that there are different types of production systems – as hinted at in our qualitative discussion, “projects are designed to produce something, so they must be some sort of production system.”

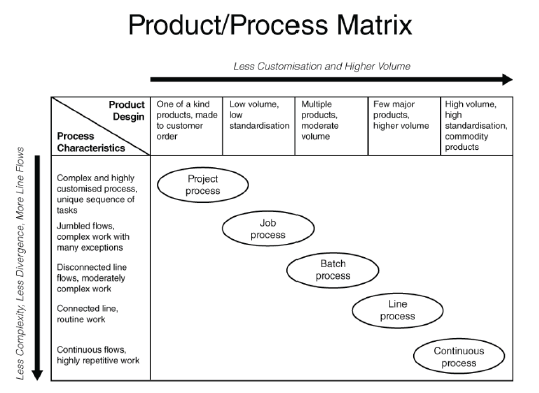

The classification of different production systems was explored in a comprehensive manner by Hayes and Wheelwright in two seminal papers [2 – 3] published in the Harvard Business Review in 1979. They codified the notion of the Product-Process matrix, classifying different types of production systems along two dimensions. One dimension considered the product structure: the type of product being produced, ranging from unique (one-of-a-kind) to commodity (high volume). The other dimension considered the nature of processes used in the system to produce the product (continuous flow, job shop or project). This turned out to be a very useful framework for understanding strategic choices available to a company in matching production processes to the requirements of a product’s lifecycle.

Others subsequently elaborated on the Product-Process matrix, notably Schmenner [4], as shown below in Figure 1. A key addition to the matrix is the category of project in the upper left-hand corner of the matrix. Figure 1 shows various types of processes that could be used to produce products with different characteristics, ranging from a unique, customized, one-of-a-kind product to a mass commodity. While the classification of process types is somewhat dated (worker-paced vs. machine-paced might have been appropriate in 1981, but perhaps less so today) the principle of adapting the processes used, depending upon the characteristics of what is being produced, remains quite valid.

As described in Hayes and Wheelright’s articles [2 – 3], different companies working in a variety of industries can be viewed as occupying different regions of the Product-Process matrix. At the bottom right-hand corner are mass commodities that are amenable to a continuous flow production system. Examples include refined oil products, sand, or sugar, for instance. A little further to the left, adjacent to continuous flow might be a relatively mechanized and connected production system, such as a moving assembly line, wherein the products generally have only slight variations, e.g. major appliances or automobiles. Further up the diagonal to the left might be a more disconnected production system, utilizing batch flow, wherein the volumes might be smaller and there might be more customization to customer requirements, such as heavy equipment. Next up the diagonal is a “job shop” production system, using “jumbled flow,” such as encountered in commercial printing, wherein jobs arrive in different forms and require different tasks, though the equipment is usually general purpose. Finally, at the extreme left hand corner is a project, defined as unique, custom, one-of-a-kind, and / or limited in number.

Figure 1: The Product-Process Matrix

We introduce the Product-Process matrix for two reasons. First, it shows how production systems can vary depending upon the constituent processes that comprise the system, which in turn can be selected by bearing in mind the nature of the product to be made. Second, the science of operations research and operations management – basic equations such as Little’s Law [5 – 7] and Kingman’s Formula [6 – 7], and associated analytical tools and techniques, such as queuing theory – apply to any of the production systems, because they apply to the underlying processes. At the most fundamental level, any process involved in any of the production systems mentioned in Figure 1 comprises a sequence of tasks or activities which aim to transform materials, resources and / or information to satisfy the demand of a subsequent process, as explained in detail in Factory Physics [8, pp. 45 – 111]. Whether the processes are uniform or subject to all manner of variability and non-uniformity, such as batching, key parameters such as throughput, cycle time, WIP and capacity utilization can be described using the analytical tools of operations research and management [8, Ch. 7 – 10]. These examine at length the consequences of interconnecting such processes, and their aggregate behavior within a system.

In other words, the Product-Process matrix provides a unifying framework to understand production systems, with the same theoretical principles applying to any of them. Making this observation allows us to apply the tools of operations management to model any of these production systems and optimize them, as we at the Institute have advocated for [10], using the PPM framework illustrated in Figure 2. The ability to model project execution, to predict the limits of performance, to model how variability propagates across the different dimensions of a project, and to identify where best to implement control mechanisms to mitigate and manage variability is what distinguishes PPM from other methods and practices that are advocated for improving project execution and delivery. No other discipline for project management has a theoretical framework that uses actual data from outcomes on project activities to predict limits on project execution performance and identify what is genuinely achievable.

Figure 2: Project Production Management Framework

How is this operationally useful for executing capital projects, which lie at the upper left hand corner of Figure 1? Through experience at the Institute, the projects we have come across have simpler elemental production systems embedded within their work activities. The sheer size and scale of the capital projects our members execute are large enough that improvements gained by using the tools of operations management to analyze and optimize the entire system are material.

The observation that the work activities in a capital project can be decomposed into a set of simpler production systems is easily appreciated when considering the example of a generic construction project. The mixing and pouring of concrete is generally a continuous flow process, as is that of piping. Looking at the manufacturing and delivery of fasteners to a site, extending the “production system” all the way from the project owner up to through the supply chain, it is clear that the production of fasteners are a line flow, a mass manufacturing system. Whereas pipe spools, with their varying specifications, are engineered to order (ETO) components and therefore are the domain of job shops.

With PPM, one can map all these production systems, understand their linkages, use the analytical tools of operations research to model and predict their behavior under various assumptions of variability, and design appropriate production control mechanisms to mitigate and buffer the effects of variability. Once the nested production systems are mapped, one can apply the analytical tools of operations management to understand where bottlenecks and WIP build-ups occur, calculate and analyze system performance using the fundamental measurements of throughput, WIP, capacity and cycle times, and reconfigure processes and allocate buffers to optimize system performance. In a future paper, we’ll elaborate on the methods and processes one can use to identify the different production systems inherent in a project.

It is important to note that throughout the preceding discussion, nowhere have we relied on the notion of “standardized” product to discuss the inherent repeatability in project work activities. It’s all about standardizing the process, rather than standardizing the product, although in those circumstances wherein products can be standardized, that may offer additional advantages for project execution. The points made in the preceding discussion are best illustrated by looking at two examples.

The first example is the fabrication of an offshore oil & gas rig, comprised of the following main components: skirt piles, jacket, deck and bridge. Figure 3 replicates the Product-Process matrix, showing the different types of production systems embedded within the overall project, overlaid onto the Product-Process matrix.

Looking at the overall project, the entire assembly including all sub-systems, transportation, subsea tiebacks and set-in-place activities constitute a jumbled flow at the top left hand corner of the Product-Process matrix.

Figure 3: Product-Process Matrix used to analyze activities in fabrication of offshore rig

However, within the overall project, one can identify distinct production systems embedded within the work activities. For instance, the design, engineering and fabrication, including the supply chain and delivery logistics of custom elements, such as the post tension legs made of specialized steel, are a prototypical job shop activity. The design, engineering and fabrication of the subsea umbilical structure is similarly a job shop production system.

Welding, with access to a finished goods inventory, is an example of a batch flow production system. A critical question to understand is the appropriate batch size for the inventory to best use the available capacity (number of welders), as well as completing the welding activities in the correct sequence to smoothly transition to the subsequent project work activities. Having too much inventory, i.e. too large a batch size, can draw one to incorrectly infer that more capacity (welders) is needed, though the additional cost may not actually accelerate the schedule.

Finally, fabrication of the specialty-welding rod required for the massive amount of welding is an example of a continuous flow system.

Figure 3 illustrates just some of the constituent production systems embedded in the overall fabrication of the offshore rig. Using this observation allows one to map all the work activities in a form amenable to modeling and simulation to understand how the various constraints – availability of resources, impact of delivery delays, limits on execution times – affect the overall execution of the project in terms of cycle times, throughput, inventory levels and finished tasks.

Figure 4: Illustrative breakdown of overall rig fabrication construction system into constituent production systems

Figure 4 illustrates how the overall production system might be decomposed into constituent production systems, each feeding into an overall site assembly flow. As our discussion is necessarily high-level, only a part of the overall production system is drawn, recognizing the job-shop nature of the post-tension leg and subsea umbilicals, while also recognizing the continuous supply flow of the welding rod needs no engineering design but does entail fabrication and delivery to maintain appropriate inventory levels. Other components of the overall rig, which we have not discussed here, would have their own production systems, as dictated by the position of the product structure on the Product-Process matrix. In a future paper, we’ll elaborate on the mechanics of linking up these disparate production systems, using the analytical tools of operations research and sciences to optimize overall throughput, minimize cycle time and limit WIP in the system.

Our second example is a large infrastructure project: Heathrow Terminal 5. It is a famous example that has been written about extensively [11 – 15]. There are many aspects in which Heathrow Terminal 5 was innovative. For instance, the accompanying article by Jennifer Weitzel and Kerry Haley later in this Journal discusses the optimization of the supply flows, noting the unique constraints on access to the construction site. Our purpose is to highlight that such a large complex project, which consisted of 16 discrete projects and 147 subprojects, could be decomposed into several production systems, which could then be analyzed and optimized using the tools of Project Production Management. In their article, Weitzel and Haley cite the specific example of the expanded polystyrene panel supply chain [14].

Here we consider a separate example, the production system supplying rebar to the Terminal 5 construction site. This example clearly depicts how the application of various PPM principles can be used to pinpoint opportunities to compress cycle time, including the role PPM principles play in identifying how other technologies such as 3D modeling can optimize performance.

As the work onsite commenced, throughput of site production exceeded engineering production. Initial remedies to this problem included adding third party engineering capacity. However, a quick exercise with stakeholders representing various operations within the rebar production system revealed the opportunity to reduce cycle time, WIP and the need for capacity was sufficient enough to avoid adding engineering capacity.

In this instance, the value stream was well understood and well under control. Raw rebar was shipped into a T5-dedicated fabrication facility, enabling control of all rebar activity other than the manufacturer of the rebar itself and transportation to the T5 fabrication facility. To minimize the impact of any variability associated with the manufacturing process and transportation, an inbound raw material inventory buffer was held at the fabrication facility, using a minimum / maximum policy for the amount to be held at any given time. Standardization of various design elements was also used. This included “chairs” for underground “cut and cover tunnels,” structural walls, etc. With the front end of the value stream fairly robust and the design optimized, the next step was to optimize the onsite production system.

Figure 4: Initial mapping of rebar production system

Figure 5: New rebar production system, compressing cycle time

While looking for opportunities to compress the overall cycle time for the rebar production system, it was noted that a large percentage of the six-week lead time was the consequence of a complicated set of iterations between design, assembly and engineering. The introduction of a rapid study, bringing together engineering, assembly and fabrication stakeholders, coupled with the use of innovative digital technology for visualization of the fabricated parts and the steps required to install them using a 3D model of the construction process, eliminated most of the iterations responsible for the six-week lead time and culminated in a final process with a lead time of five days, shown in Figure 5. To control WIP, an important feature was to install a CONWIP control mechanism to trigger the release of work at the detailed engineering stage.

Figure 6: Heathrow T5 Rebar Production System

The end results from applying PPM to the rebar production system once identified within the Terminal 5 construction project were substantial. The lead-time for rebar drawing was reduced from six weeks to roughly five days. Most of the rebar drawings, up to 75%, could be detailed for pre-assembly. Designing for pre-assembly saved 20% on installation times. The rebar installation cycle times were reduced from two weeks to three days.

When introduced to Project Production Management, experienced project practitioners often question its applicability to large capital projects, because they think the tools of PPM are not applicable to the unique, custom “one-off” nature of capital projects. The Product-Process matrix helps clarify that large capital projects generally have different types of production systems embedded within their work activities, and all are amenable to the application of PPM. By using the Product-Process matrix as an aid to map the production systems inherent in a capital project’s work activities, the power of PPM can be brought to bear on optimizing project performance. Two real-life examples, drawn from the oil & gas and civil infrastructure construction industries, illustrate this approach.

Several conclusions can therefore be drawn to dispel common misconceptions and suggest gaps in current project delivery, which PPM can uniquely address, and will be covered in future papers by PPI. First, to view PPM as drawing an analogy between line flow and high volume manufacturing, with work activities in projects, is overly simplistic and wrong. Most project practitioners are confused by this incorrect analogy, which they cannot reconcile with the unique scope and custom nature of their projects. As explained here, a deeper analysis, using tools such as the Product-Process matrix, reveals the inherent repeatability of knowledge, process and underlying product structure, to which the tools of operations research can be applied. This leads to the conclusion that even projects of unique scope and custom products can be decomposed into simpler production systems using standardized knowledge, standardized processes and even standardized components. Future papers in this Journal will address the mechanics of decomposing projects into simpler production systems, and the application of elementary relationships using Little’s Law and Kingman’s Formula, among other modeling techniques, to understand the limits of project execution performance, the use of rules and policies to design and control work activities, and the optimal placement of buffers to manage variability.

1. The Concise Oxford Dictionary of English Etymology, Oxford University Press, 1996.

2. R. Hayes and S. Wheelright, “Link Manufacturing Process and Product Life Cycles”, Harvard Business Review, January-February 1979, pp 133-140.

3. R. Hayes and S. Wheelright, “The Dynamics of Product-Process Lifecycles”, Harvard Business Review, March-April 1979, pp 27 – 136.

4. R. Schmenner, “Production/Operations Management: Concepts & Situations”, Science Research Associates, July 1981, 4th Edition by Macmillan, April 1990.

5. J. Little, “Little’s Law as viewed on its 50th Anniversary”, Operations Research, Vol. 59, No. 6, May-June 2011, pp 536-549.

7. P. Morse, “Queues, Inventories and Maintenance: The Analysis of Operational Systems with Variable Demand and Supply”, John Wiley & Sons, 1962, Dover Phoenix Edition, 2004.

8. W. Hopp and M. Spearman, Factory Physics, Third Edition, Waveland Printing Press, 2011.

9. E. Pound, J. Bell and M. Spearman, Factory Physics for Managers, McGraw Hill, 2014.

10. R. Shenoy, and T. Zabelle, “New Era of Project Delivery – Project as Production System”, Journal of Project Production Management, Vol 1., November 2016.

11. “Managing Structural and Dynamic Complexity: A Tale of Two Projects”, Project Management Journal, Vol. 45, No. 4, 2014, pp 21 – 38.

12. R. Arbulu, G. Ballard, and N. Harper, “Kanban in Construction”, Proc. IGLC-11, 2003.

13. R. Arbulu and G. Ballard, “Lean Supply Systems in Construction”, Proc. IGLC-12, 2004.

14. R. Arbulu and G. Ballard, “Linking Production-Level Workflow with Materials Supply”, Proc. IGLC-13, pp 199 – 206.

15. R. Arbulu, “Application of Pull and CONWIP in Construction Production Systems”, Proc. 14th Annual Conference of the International Group for Lean Construction, July 2006, pp 215 – 226.

Ram Shenoy is Technical Director and Chair of the Technical Committee of the Project Production Institute. He is also CEO of the RBR Group, a technology product and service commercialization company working with venture capital and private equity firms on issues of technical strategy and business development in the energy sector, as well as Fortune Global 500 clients, with offices in Silicon Valley, Houston and Dubai.

Shenoy spent 20 years with Schlumberger Ltd., starting as a research scientist and then holding a variety of roles of increasing responsibility across the spectrum of research, development, commercialization and operations support across the world. His last position with Schlumberger was as Vice President of Research, leading Schlumberger’s global corporate research laboratories.

He subsequently became Chief Technology Officer of ConocoPhillips, a position he held for four years. Shenoy serves on the boards of a couple of startup companies, and a number of advisory boards, such as the Board of the Houston chapter of TIE, a global association of entrepreneurs and angel investors. From 2013-2017, he served on the U.S. Secretary of Energy Advisory Board, as the sole representative from the oil & gas industry.

He has a B.A. and M.A. from the University of Cambridge UK, a PhD in Electrical Engineering from Cornell University, and an MBA from the Stern School of Business, New York University.