The engineering and construction industry is undergoing a transformative shift with the adoption of innovative practices aimed at enhancing project performance and competitiveness. Among others, Industrialized Construction has been utilized mainly in Europe and North America for over two decades. Based on a framework developed for IC housing projects, IC encompasses a broader approach that integrates nine components: planning and control of processes, developed technical systems, prefabrication, long-term relations, logistics, use of ICT, re-use of experience and measurements, customer and market focus, and continuous improvement. However, E&C industry practitioners often equate IC with offsite construction or “prefab,” overlooking its broader scope. This paper shifts focus to analyze how production systems provide a production-centric layer in an IC context, emphasizing the levers of production system optimization: process design, product design, variability, inventory and capacity. By examining the impact of these elements on the nine components, standardization, modularization, and physical decoupling, this study demonstrates how Project Production Management can facilitate the integration of these components in an IC context, by aligning them towards a common production goal and improving project performance.

Keywords: Project Production Management; Industrialized Construction; Operations Science; Production Systems; Integration.

The engineering and construction (E&C) industry continues to face significant challenges in terms of productivity, cost overruns, and schedule delays [1]. In response, the industry has embraced various innovative approaches for the last 30 years to improve project performance. One of these approaches is Industrialized Construction (IC), which offers a comprehensive framework for transforming traditional construction practices. While IC has been implemented across Europe and North America for over two decades [2], its full potential remains largely untapped due to misconceptions about its scope and application. A critical issue within the E&C industry is the common misconception that equates IC with merely offsite construction (or prefabrication), despite several authors defining IC as an integrated process that includes more components than prefab [2, 3, 4, 5, 6]. This reductionist view fails to capture the comprehensive nature of IC, and as a result, many IC initiatives fall short of achieving their intended benefits because they focus exclusively on prefabrication while neglecting other critical aspects of IC.

This paper addresses this problem by examining how Project Production Management (PPM), and its foundation of Operations Science (OS), can enable the integration of IC components. While previous studies have examined individual aspects of IC or PPM to specific construction challenges [7, 8, 9], there is limited research on how PPM can holistically enable the effective implementation of IC. This paper addresses the research question: How can PPM enable the effective integration of IC components? By leveraging the five levers of production system optimization (PSO) as an analytical framework, this study examines their role in harmonizing IC’s nine components from a production system perspective. Consequently, the objective of this paper is to develop the foundations of a coherent framework to demonstrate how PPM facilitates the systematic integration of IC practices beyond mere prefabrication.

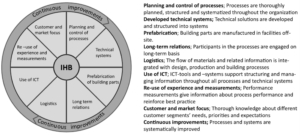

IC has evolved since its inception, yet its definition varies across literature. Qi et al. [10] states that IC involves a set of construction methods that advances the process from design through construction by employing intelligent manufacturing, automation, and digital techniques. UC Berkeley’s P2SL [11] defines IC as the fabrication of building components and systems by employing digital tools in a factory setting. PPI defines IC as “The application and use of high-volume manufacturing methods and technologies to the delivery of capital projects, including the use of product development, flow-based production processes and automation [13].” For clarity, this paper adopts the definition provided by Lessing & Berge [2], which states that IC represents “a systematic, controlled, and standardized production process of well-defined elements and building systems, which facilitates the collection of experiences from the design, production, and assembly of the building system as a basis for continuous improvements.” The selection of this definition is deliberate as it aligns with the integrative nature of IC that this paper seeks to explore. Figure 1 displays the nine components of the IC framework.

Figure 1: IC framework with its nine components based on Lessing [12]

OS is defined by the PPI as “the study of the transformation of resources to create and distribute goods and services” [13], focusing on the interaction between demand and production, variability, and the buffers required to synchronize them. PPM is the development and application of modern production theories, principles and methods to better understand, control and improve project delivery, including OS, digital and autonomous technologies. PPM is particularly relevant to IC as it focuses on how production systems are designed and controlled to achieve project objectives efficiently [13]. Unlike traditional project management’s focus on schedules (what should happen), OS and PPM provide a technical construct to examines how production systems behave and how they should behave to effectively achieve certain objective. Central to PPM are the five levers of PSO: product design (standardization, modularization, and interface mechanisms), process design (operation sequences and work execution methods), capacity (maximum flow rate through a system), inventory (accumulated entities within or between processes), and variability (dissimilarities between operations or demand) [17]. These levers are interdependent—decisions about one impact the others, and this scientific approach provides mathematical relationships like Little’s Law, and Variability-Utilization-Time (VUT) equation to enable precise optimization beyond what traditional project management approaches can achieve. Furthermore, the design and optimization of production systems is a major focus of OS and PPM, making it applicable to IC, which emphasizes systematic and controlled production processes. This also includes the understanding of standardization, modularization, and customer order decoupling point (CODP) to control the production system behavior.

Previous literature provides information about the means in which Lean Construction methods and tools interact with PPM to enhance project performance. While Lean Construction provides practical implementation tools, PPM offers the mathematical foundation for understanding production system behavior through time, inventory, and capacity buffers [14], addressing the critical limitation identified by Zabelle & Arbulu [15] that ” by using traditional project management techniques, the resulting production system cannot satisfy the schedule demand.” Previous research has laid the groundwork for integrating OS with IC. Studies by Prado [8, 18], and Zhang et al. [9] demonstrated OS applications in both on-site and off-site construction. Prado’s healthcare building case study [18] revealed how OS principles provide more accurate prediction of construction performance, while Zhang’s research [9] in modular bathroom pod manufacturing showed significant reductions in inventory investment while maintaining high fill rates. These studies consistently demonstrate that OS provides practical tools for reducing production variability and optimizing resource allocation. However, most research has focused on isolated aspects of IC rather than examining holistic integration across all nine components [12]. Furthermore, Zabelle [19] positions OS as the technical foundation for construction modernization, emphasizing the need to implement production-based approaches, which is also the vision of PPI.

This research employs a qualitative theoretical analysis to examine how PPM (as part of OS) enables the integration of IC components. This approach is appropriate for addressing this paper’s research objective as it allows for an in-depth exploration of the complex relationships between five PSO levers and IC components without requiring extensive empirical data collection, which would be premature given the nascent state of research in this area. These are the two key steps:

The analysis draws on theoretical literature, established PPM methods, and industry practices in IC implementation, which provides context-rich insights that support theory development while maintaining analytical rigor.

Conceptual Framework And Production System Analysis

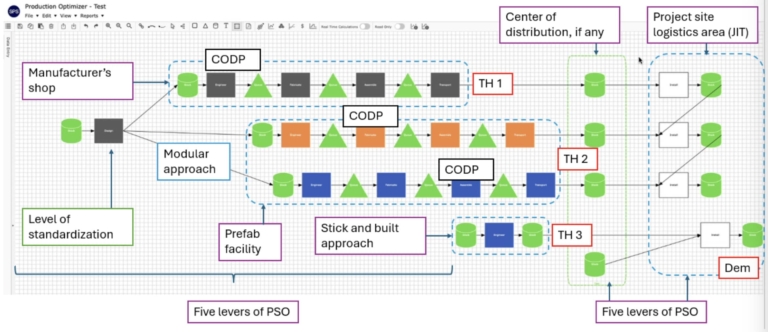

Figure 2 presents a production system map for a typical IC project (using PPI’s Process Mapper), showing the key production operations, material and information flows (the 4 verbs), which will be helpful to show the interfaces with the nine IC components. The map highlights how the PSO levers influence the network of production systems of the project and reveals several key insights into how PPM enables IC:

Figure 2: Production System Map for a Typical IC project (example).

The production system perspective showed in figure 2, grounded in PPM, provides a powerful framework for integrating the nine components of IC.

This production system analysis provides a common language and visual framework that helps stakeholders see how their specific IC component connects to the larger system. Instead of optimizing components in isolation, the OS approach reveals interdependencies that require coordination across all nine components.

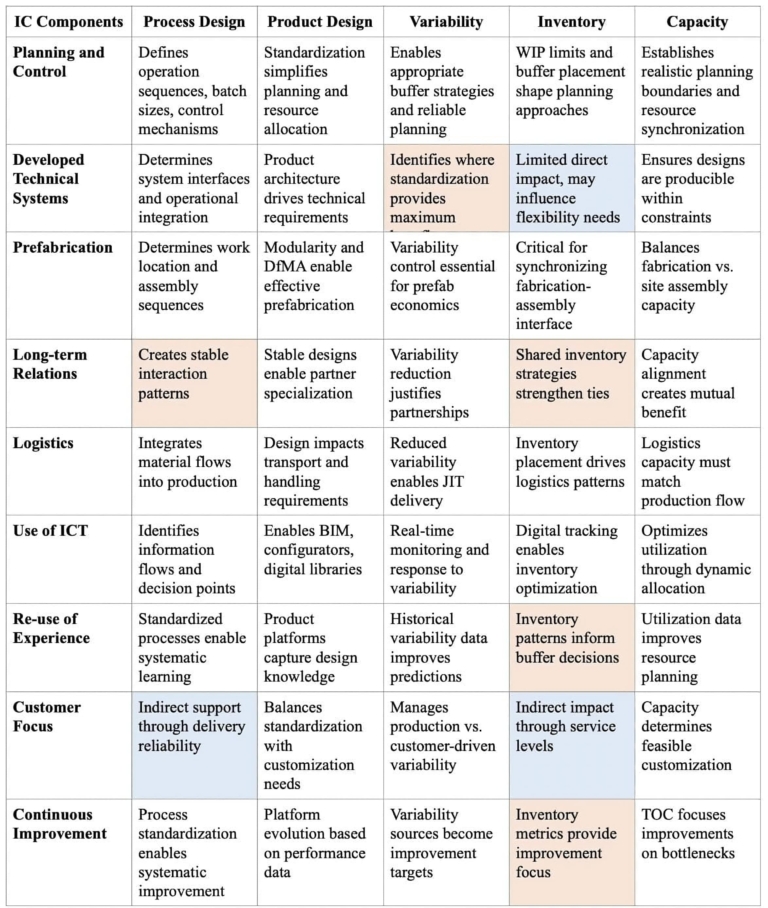

This subsection presents the interrelation between PSO levers and the IC framework components. Please note that all levers affect all IC components at different levels, which table 1 present. In the following paragraphs, this study will mention how each lever interacts with each IC component.

Table 1: Interactions between PSO levers and IC components. For each cell, white background means enabling relationship, orange means moderate direct relationship, and blue mean indirect relationship.

This study contributes to the theoretical understanding of IC by demonstrating how PPM facilitates systematic integration of IC components using PSO levers. The findings extend beyond the conventional view of IC as merely offsite construction toward understanding IC as an integrated production system, aligning with Lessing’s comprehensive definition while providing the scientific foundation to operationalize it. The production system map developed provides a visualization tool that reveals interconnections between seemingly disparate IC components, making the dependencies requiring coordination for successful implementation visible. This addresses the fundamental challenge that many IC initiatives fail to achieve their intended benefits by focusing exclusively on prefabrication while neglecting other critical aspects. The lever-component mapping analysis demonstrates that PPM serves as a comprehensive framework for implementing IC by providing production-related metrics to analyze production system behavior and establish an extra layer for analyzing the IC components. While earlier studies demonstrated OS value in specific construction scenarios, this research shows how the five PSO levers enable all nine IC components, addressing the fragmented application of IC practices identified in the research problem.

From the 45 interactions between the 5 PSO levers and the 9 IC components, 37 were directly enabling, 5 moderately direct relationship, and 3 indirect relationship, proving a most enabling nature of the interactions between the levers and the components. It seems that product design and capacity are the most enabling levers for IC, and the inventory lever seems to have a less direct relationship than the other levers. However, the interconnecting nature of the 5 levers also plays a role in the interactions with IC components, and avoiding one of these levers can create unintended consequences of an IC endeavor (i.e., bad positioning of an CODP for an prefabricated element). This study demonstrates that successful implementation requires attention to all nine components within a production system framework. The production system map serves as an adaptable template for visualizing crucial flows, while the PSO levers framework offers systematic guidance for analyzing IC components as part of a network of production systems, following the PPI vision of projects and how to improve them. Moreover, it’s important to acknowledge the limitations of this study, such as the chosen IC framework, the type of infrastructure (buildings), the focus on the production system side of IC, and only using PSO levers from PPM and OS.

This study has addressed the research question: How can PPM enable the effective integration of IC? Through systematic analysis of the PSO levers and their relationship to the nine IC components, this research demonstrates that PPM provides a scientific foundation that transforms IC from separate practices into an integrated network of production system. The findings reveal that PPM enables IC integration through three key mechanisms: mathematical foundation for understanding production system behavior through models like Little’s Law and VUT equation, a common production-focused language bridging traditionally separate domains, and production-based decisions, such as CODP positioning, buffer allocation, modularization level, etc. This research contributes to construction engineering and management practices by providing a production-centered lens for analyzing IC implementation that goes beyond traditional project management approaches. The mapping of PSO levers to IC components creates a coherent framework that explains why certain IC practices are effective and under what conditions they produce optimal results. This study offers a structured approach for designing and optimizing IC production systems, with the production system map serving as an adaptable template and the PSO levers framework providing systematic guidance for analysis and improvement. The integration of PPM with established construction practices creates practical implementation pathways that combine theoretical rigor with operational applicability.

Future research should empirically validate the proposed framework through case studies, extend the analysis to other OS-based frameworks (not only the PSO), using different IC frameworks and different types of infrastructure, and address the other limitations of this study. PPM enables construction organizations to move beyond fragmented applications to achieve the full potential of IC, ultimately improving project outcomes through enhanced productivity, reduced costs, and more reliable schedules.

[1] R. G. Shenoy and T. R. Zabelle. (2016). “New Era of Project Delivery – Project as Production System,” Journal of Project Production Management, vol. 1, no. 1.

[2] Lessing, J. & Brege S. (2017). Industrialized Building Companies’ Business Models: Multiple Case Study of Swedish and North American Companies. Journal of Construction Engineering and Management. 144 (2).

[3] Hall, D., Lessing, J. & Whyte, J. (2022). New Business Models for Industrialized Construction. Chapter in Industry 4.0 for the Built Environment. Springer International Publishing.

[4] Bing Qi, Mohamad Razkenari, Aaron Costin, Charles Kibert & Meiqing Fu. (2021). A systematic review of emerging technologies in industrialized construction. Journal of Building Engineering. 39.

[5] National Renewable Energy Laboratory. (2023). Industrialized Construction Innovation.

[6] Autodesk. (2022). Industrialized construction disciplines the building process with data.

[7] Prado, G. (2022). Operations Management Concepts Applied to Offsite Construction. Proceedings of 2022 Modular and Offsite Construction (MOC) Summit, Edmonton, Canada, 225-232.

[8] Prado, G. & Tommelein, I. (2023). Application of Operations Science to Design a Project Production System: A Case Study in Building Construction. PPI 2023 Technical Conference.

[9] Zhang, B. & Fischer, M. (2024). Match Supply with Demand: A Case Study Implementing Production System Optimization (PSO) for Offsite Construction. PPI 2024 Technical Conference.

[10] Bing Qi, Mohamad Razkenari, Aaron Costin, Charles Kibert & Meiqing Fu. (2021). A systematic review of emerging technologies in industrialized construction. Journal of Building Engineering. 39.

[11] Project Production Systems Laboratory. (2023). Industrialized Construction Initiative.

[12] Lessing, J. (2006). Industrialized house-building: Concept and processes, Dept. of Construction Sciences, Lund Univ., Lund, Sweden.

[13] Project Production Institute. (2023). Glossary.

[14] Spearman, M. (2023). Lean Demystified: Operations Science Explains and Expands Lean. PPI 2023 Technical Conference.

[15] Zabelle, T. & Arbulu, R. (2024). Schedules vs Project Production Systems. PPI 2024 Technical Conference.

[16] Zabelle, T. (2018). Operations Science View of Value Stream Mapping. Journal of Project Production Management. 2.

[17] Project Production Institute. (2020). Five Levers Of Production System Optimization. PPI Technical Guide 01.

[18] Prado, G. (2022). Impact of Production Systems Design on Project Performance: An Operations Science Analysis on a Case Study in Construction. Master of Science Thesis, Engineering and Project Management Program, University of California, Berkeley, CA.

[19] Zabelle, T. (2021). Modernization of Construction – What it is and how to make it happen. PPI Eight Annual Symposium.

[20] Lessing, J. (2015). Industrialized House-Building, Conceptual Orientation and Strategic Perspectives. Faculty of Engineering, Lund University, Lund.