The Product-Process Matrix, first proposed by Hayes and Wheelwright, is a fundamental concept in Operations Science. Products made in production systems vary in complexity, ranging from highly customized low volume products to commodity, standard high-volume products. The Product-Process Matrix describes how certain types of production processes are more naturally matched for some product-volume mixes compared with other types of processes. Hayes and Wheelwright used this idea to describe the variation with product volume of strategic options for companies, ranging from low volume, highly customized products to high volume commoditized products.

Schmenner extended the Product-Process Matrix concept by explicitly positioning projects as one type of product at one extreme of the matrix – a unique one-of-a-kind custom product. We argue here that a more fruitful direction is to view a project as an aggregation of different production systems, as pointed out in an article in a previous volume of this Journal. The processes for each type of production must be carefully matched to the type of production taking place, in order to optimize overall project execution performance. An interesting direction to explore is to understand whether more precise relationships can be formulated between the variability of product types being made and how the processes should be chosen to manage that variability.

Keywords: Product-Process Matrix; Operations Science; Process Lifecycle; Product Lifecycle; Project Production System

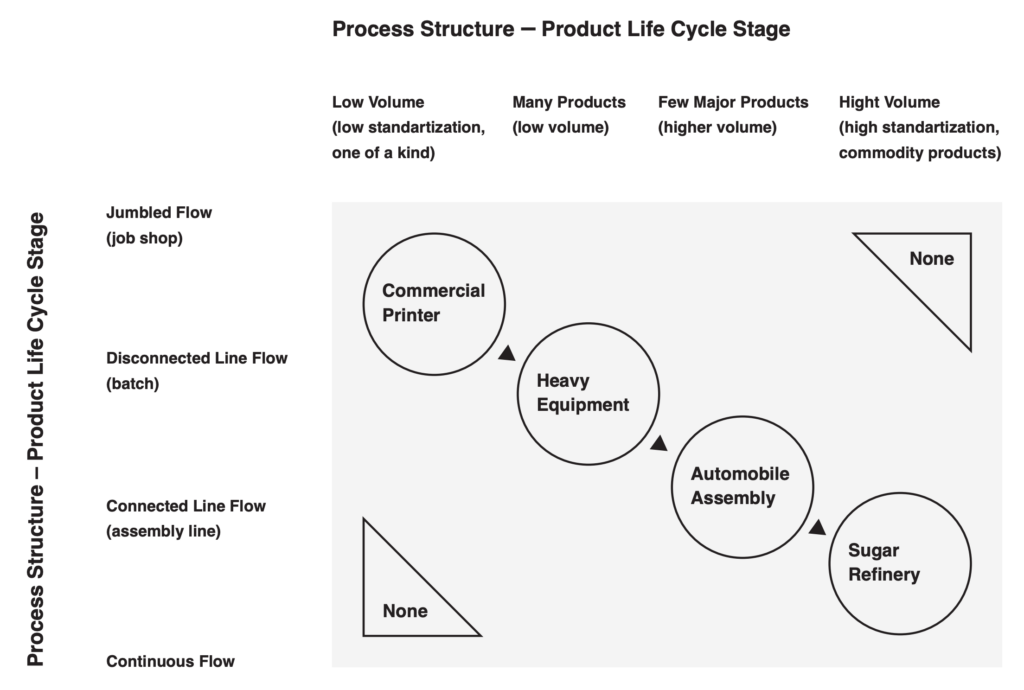

The Product-Process Matrix was first introduced by Hayes and Wheelwright in [1] [2].They were preoccupied with the lifecycle of products manufactured by companies, and concerned with the strategic options available to companies in matching the “process lifecycle” to the products they were manufacturing. Accordingly, they chose to map products, parametrized by complexity and volume, against the different types of production processes that can be used to fabricate the products, illustrated in Figure 1.

Figure 1: The original Product-Process Matrix proposed by Hayes/Wheelwright

Figure 1: The original Product-Process Matrix proposed by Hayes/Wheelwright

Hayes and Wheelwright examined where different companies are located within the matrix, why they are at that location, and in which direction they should or should not move. Although they find the diagonal from the upper left to the lower right side of the matrix to be the most likely position of a company, they also analyzed good reasons why companies could choose positions above or below the diagonal. They found that “an industry usually progresses down the diagonal of the matrix.” Looking at the home building industry in the U.S., however, they find that the products have become less standardized, and that the industry therefore has moved in the opposite direction. They found that reason for this was due to “the inability of the market to standardize.”

Hopp and Spearman [3, pp. 9-10], discuss the Hayes-Wheelwright thesis in which higher product volumes tend to go hand-in-hand with smoother flow process structures. They also explicitly articulate that production systems might evolve with the product lifecycle. Starting with research prototyping with high degrees of customization and low volumes at the top-left hand corner of Figure 1, as a product matures, with greater standardization and greater volumes, production processes might evolve along the diagonal towards the bottom-right hand corner. However, they conclude by warning that the product-process matrix is overly simplistic to define production strategy, remarking that if it was simply a matter of picking a volume-complexity position to define what production system to use, one would not need Operations Science in the first place. They support this conclusion by observing that modern manufacturing tries to combine high-volume flow lines with flexibility and customization (what is now called mass customization).

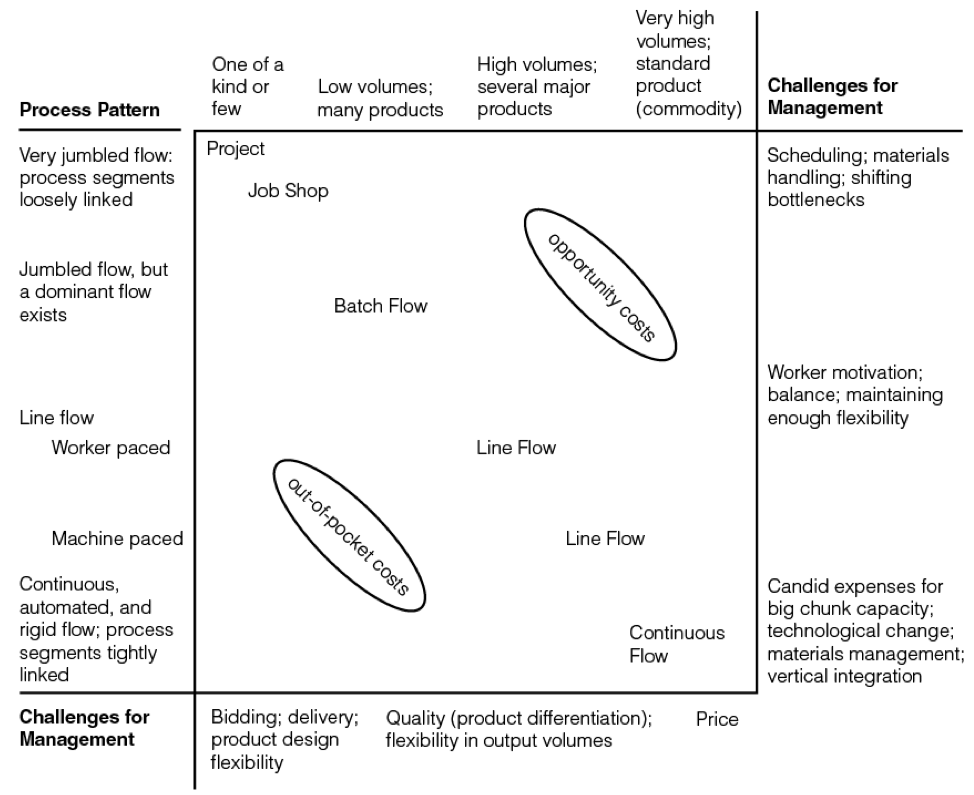

Schmenner [4] took the Product-Process matrix to explore the choices made by production/operations managers. He also made a distinction between manufacturing and service operations, and explicitly considered projects unique from either because of additional requirements:

Figure 2 shows Schmenner’s proposed positioning of projects along the Product-Process Matrix.

Figure 2: Schmenner’s Modification of the Product-Process Matrix [3]

Figure 2: Schmenner’s Modification of the Product-Process Matrix [3]

Schmenner correctly observes that projects comprise a mix of production activities – both manufacturing and service operations. For instance, physical objects such as pipes, beams and rebar used in major capital projects naturally require some set of manufacturing operations. It is also true that many service operations take place during a major capital project – engineering design, welding and installation activities, delivery – any activity requiring human capital and specialized skills calls for some service operation in the pursuit of project execution.

We therefore argue that the correct way to view projects with respect to the Product-Process Matrix, is that the matrix offers a menu of process types for the different types of production that must take place within a project, as illustrated in Figure 3. A project should be viewed as network of connected production systems, each tailored for the production activity required for project execution. This observation has earlier been made by the Institute in its position paper [5]. Operations Science can be brought to bear in optimizing the constituent production systems, using familiar relationships such as Little’s Law and the VUT equation, so as to optimize overall project execution performance. This is a subject for future articles in the Journal.

Figure 2: PPI’s proposed Product-Process Matrix

In any major capital project, one can easily identify all the different types of processes listed in Figure 3 by examining them at a sufficient level of detail. Examples of the different types of processes that one might encounter in a typical capital project are listed below:

Continuous flow – This describes production processes where the product flows continuously rather

than being divided into discrete units. The obvious example in construction is the mixing and pouring

of concrete.

Connected line flow (Assembly line) – This is the typical production process most people associate with high volume manufacturing, such as automobiles. It can be used when the products to be made are sufficiently high in volume, but individual discrete units. The product range is also sufficiently narrow to have a continuous production system, usually highly automated, where the fabrication operations for each product are uniform from product to product and can be executed continuously and uninterrupted. An example might be a production system to manufacture the millions of fasteners that might be used on a construction site.

Disconnected line flow (Batch) – Production using batch processes is used to make similar items on a repeat basis, where the volumes are not high enough to allow the economic use of a connected line flow. Batch production also permits a wider range of products than typical continuous flow. An example that can occur in capital project is anywhere one is making multiple units or modules of the same type for a large plant, e.g., cooling units used in data centers, or compressors or other types of rotating equipment used in large industrial plants.

Jumbled flow (Job shop) – This type of production is typically used where the products to be made vary significantly in form and structure, materials and processing required from unit to unit, with each individual unit being highly customized. Machine shops are the most familiar example of this type of production. Anything that is engineered to order in a capital project, where the units are small in volume, with high degrees of customization will almost certainly be produced using jumbled flow.

We have reviewed the history of the Product-Process Matrix. For the purposes of optimizing project execution performance, we have argued that projects are properly viewed as networks of production systems. Operations Science provides a proven scientific framework to design and optimize all the constituent production systems encountered in a project, so that overall project targets can be identified and met. The variability in process types and how it relates to the variability in product type is an interesting topic for future research.