With members representing Chevron, Google, Hess, IBM, McKinsey, Merck, Microsoft, Royal Dutch Shell, Stanford University and University of California at Berkeley, amongst many others, the Project Production Institute (PPI) is a consortium of industry professionals and academics working to radically improve capital project outcomes.

Although PPI recognizes the need for formal project management as defined by the Project Management Institute (PMI), there exists a significant gap in the current framework.

This gap results in loss of value for all owners and stakeholders involved in the delivery of capital projects, from small projects to mega projects.

Formal project management practices focus on what work needs to be done by whom when, with a heavy emphasis on project administration. While understanding this is necessary, it is not enough to ensure better project performance is achieved. The main gap in the current framework is the lack of consideration for how and where work will be performed.

Although many operate under the belief that project schedules are representations of how work will be performed, others are closing this gap by augmenting their perspective to:

Put a significant emphasis on production rates versus schedule dates,

Enable teams to manage their projects as production systems, and therefore, applying all interconnected five levers of production system optimization, and

Understand how project production systems behave using fundamental relationships such as what happens with throughput and cycle time if more work is opened, as well as what the implications are to project schedules if the utilization of capacity is maximized.

For all those adopting Project Production Management (PPM), results have materialized as increased competitive advantage in what they do, billions of dollars in cost savings and new revenue generation opportunities through quicker delivery of assets. Many have become important references for benchmarking project performance success including companies such as Chevron, Hess, Microsoft, and Royal Dutch Shell. Also, and equally important, leading academic institutions including Stanford, California Polytechnic State University, and Texas A&M are incorporating these concepts into their ongoing research efforts and in undergraduate and graduate courses in an effort to advance performance of the Engineering and Construction industry.

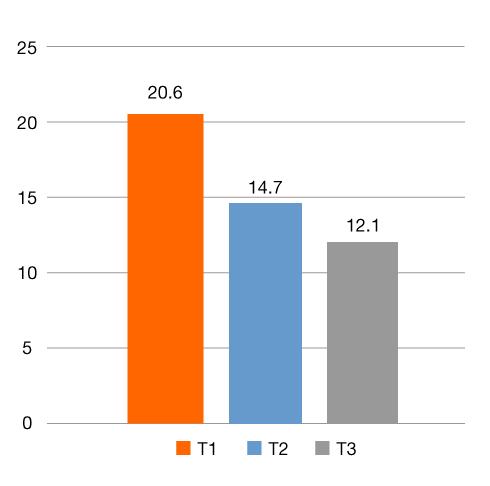

In one complex multi-billion dollar Liquid Natural Gas (LNG) project, three LNG trains were delivered with successive improvements over time through application of PPM. The owner applied PPM to address severe budget and time overruns on the project. The diagram below shows Train 1 (T1 Orange Bar) delivery of 20.6 months without PPM. When applying PPM, Train 2 (T2 Blue Bar) was delivered in 14.7 months and Train 3 (T3 Gray Bar) achieved delivery in 12.1 months. Some believed this success was due to a learning curve effect. However, the owner benchmarked against three other projects and the data showed PPM provided unique advantage that could not be attributed to a learning curve. In fact, the owner had data showing that other similar projects got worse results with later trains.

As seen in the diagram above, the application of PPM to projects can lead to over 40% improvement in schedule delivery by addressing the gap in current project delivery approaches.

The Engineering and Construction Industry is enamored with schedules and dates. Without a doubt, there is an overinvestment in reporting and forecasting of project progress, which forms the basis of project accounting, and underinvestment in how project production is planned, controlled and improved. Although monitoring progress at any given time is important, it is not the same as managing project production systems, which are the source of project performance.

By viewing a project as production system, PPM allows for industry professionals to understand how to use advances in technology to design, plan and implement their project production systems to fill in the gaps of traditional project management. Traditional project schedules and project controls remain a necessary part of any capital project, but are almost always insufficient to provide the desired results for capital project delivery.

PPI was founded in 2013 and operates as a not for revenue organization. It was started by a group of industry professionals driven by the desire to end the industry’s chronic project delivery failures and by the vision of enhancing the value Engineering and Construction provides to society. For more information, read the PPI manifesto.

The Institute offers numerous ways to get involved. Membership is free.

PPI is organized around an Industry Council, a Technical Committee and various industry Working Groups. Members are recognized global leaders in capital project delivery, operations, production and supply chain management, and many have authored numerous books, papers and hold patents. These groups target the development of next practices by combining Project Production Management (PPM) and Digital Technologies for several industry markets.

In addition, PPI provides access to tools and information to address the current gap in project delivery. By working with academics and leading universities, PPI seeks to define and research next-generation solutions to today’s hard problems. See research and published articles in the PPI Journal, PPI papers, or Current Research Projects. View our glossary for a comprehensive look at the latest industry terms.

To publicize and disseminate research and information related to PPM, the Institute hosts monthly events across the globe to educate and inform both academics and industry practitioners. Sign up to attend an event or webinar. Join us at our annual Symposium. Watch recorded videos from our past digital events here.

Join us today. If you have other questions, concerns or ideas, contact us.