Once you have created your new account and successfully logged into Process Mapper, complete the steps below to create a process map:

Note: only files in .pm format can be imported

Create a new process mapper or import existing .pm file

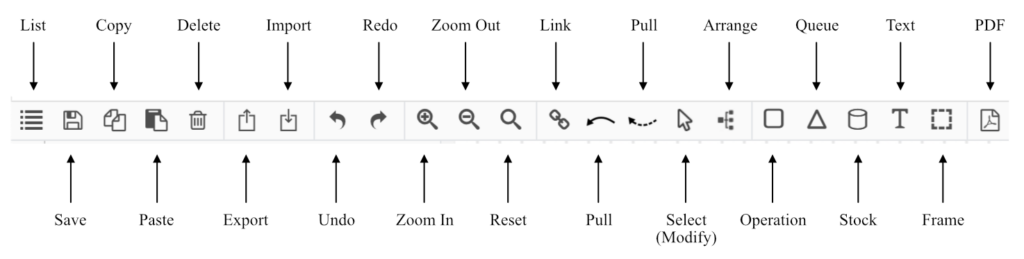

3. Once you select the process, the controls will appear in a new window. Use the following controls to create a production map.

Process Mapper Toolbar

Process Mapper Toolbar

| Key | Mnemonic | Description |

| E | Edit | Edit text of the selected shape |

| A | Arrow | Select “Modify” mode |

| L | Link | Select “Link Shapes” mode |

| O | Operation | Select “Operation” mode |

| Q | Queue | Select “Queue” mode |

| S | Stock | Select “Stock” mode |

| T | Text | Select “Text” mode |

| F | Frame | Select “Frame” mode |

Shortcuts

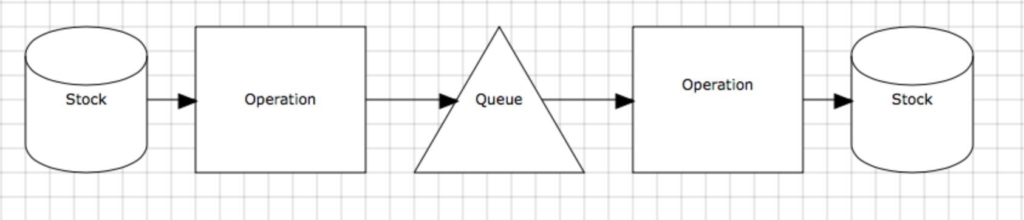

Mapping a single process is the beginning of creating a production system. Within a production system, the elements Operation, Queue and Stock are defined as:

Operation: Activities performed (by a crew or equipment) within a production system. Each operation may consist of individual tasks1

Queue: Set of objects, tasks, or other things waiting for something, typically an action to be processed in a production system2

Stock: Materials, resources, or information waiting at a point in production system for some activity to be performed on it to continue the process of transforming production system inputs into production system outputs3

Ex. single process map

Ex. single process map

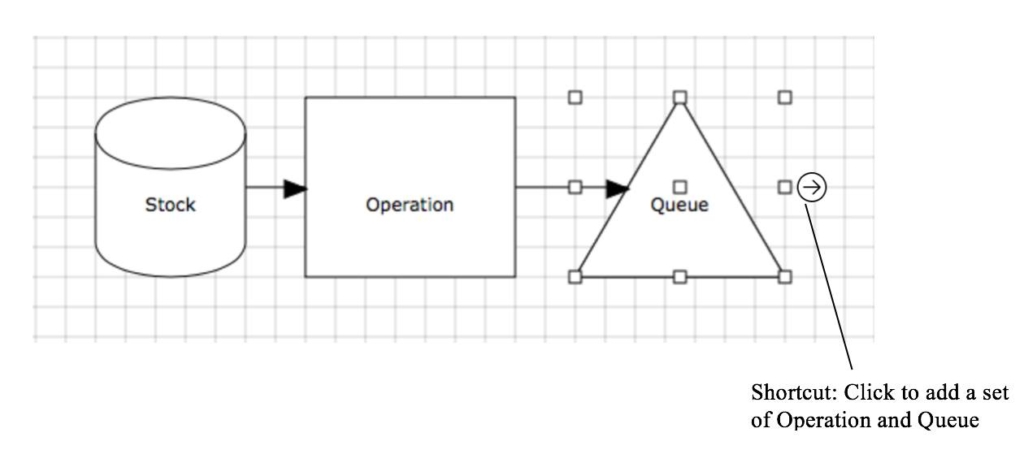

4. Select any element icon and double click on the grid for it to appear. Select Link tab and drag the mouse between elements to draw arrows that connect them. To automatically generate a set of Operation and Queue click on the desired element and the consequent circled arrow, as shown above.

As a standard rule, the sequence of production mapping begins with Stock, followed by Operation, and can conclude with either a Queue or another Stock. A complete sequence however, always concludes with Stock.

Ex. complete process map

Ex. complete process map

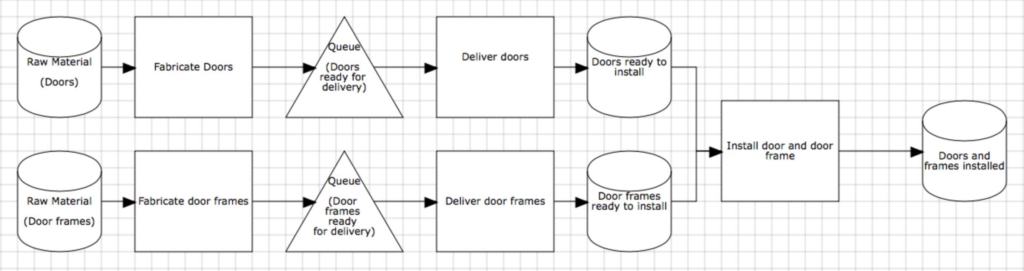

5. Once completing a single production map, it can then be expanded to include others and illustrate a complete production system.

Ex. simple production system

Production System Design: Engineering of processes, selection of resources and designation of controls to effectively transform inputs into outputs in accord with desired objectives

6. Save work before exiting the Process Mapper.

For further assistance, contact us at support@projectproduction.org

1Hopp, W.J. (2003) Supply Chain Science, Waveland Press Inc.

2Morse, P.M. (2004) Queues, Inventories and Maintenance: The Analysis of Operational Systems with Variable Demand and Supply, Dover Publications, Inc.

3Pound, E.S., Bell, J.H., Spearman, M.L. (2014). Factory Physics for Managers: How Leaders Improve Performance in a Post-Lean Six Sigma World. McGraw-Hill Education.