The global transition to net-zero emissions demands clean energy technologies that can operate at scale and cost parity with fossil fuels. However, most clean energy projects suffer from commercial unviability, technological inefficiencies, and geopolitical supply chain complexities, resulting in failures at Final Investment Decision (FID) gates. This paper examines how First Principles Thinking (FPT), combined with Project Production Management (PPM) and Operations Science (OS), can address these challenges by reengineering core assumptions and developing cost-effective, scalable solutions combined with a purpose-built delivery system that optimizes cost and schedule and improves delivery predictability.

Keywords: First Principles Thinking, Project Production Management, Operations Science, Production System Optimization, Project Production Control, Energy Transition, Clean Energy, Green Hydrogen

Keith is a seasoned capital projects executive with over 25 years of global experience delivering complex, high-value projects across the energy sector. He has held senior leadership roles at major oil and gas companies, overseeing multibillion-dollar portfolios in the upstream and energy transition sectors. His expertise spans strategy development, project gove ...

H.J. James Choo, Ph.D is Chief Technical Officer of Strategic Project Solutions, Inc. and a member of the Technical Committee for Project Production Institute (PPI). He has been leading research and development of project production management and its underlying framework of Operations Science knowledge, processes, and systems to support implementat ...

The imperative to achieve net-zero emissions by mid-century has placed unprecedented pressure on the global energy system. Clean technologies must offer reliable, economically competitive alternatives to fossil fuels. Despite substantial investment and policy support, many clean energy projects remain technically feasible but commercially non-viable [1].

Clean technology developments are ultra-low-margin, high-risk projects that rely on government subsidies to compete against their fossil fuel alternatives and are subject to complex geopolitical supply chains, as well as immature and inefficient technologies. As a result, the majority of clean energy developments fail to gain approval at the Final Investment Decision gate or, worse, undercut potential margins by delivering the project later and at a higher cost than expected.

What can be done to improve the technical and commercial viability of these clean energy projects, which are fundamental to the success of the energy transition?

This paper will explore the use of First Principles Thinking (FPT), a concept dating back to Aristotle and extensively employed by modern innovators like Elon Musk, combined with Project Production Management (PPM) and Operations Science (OS), and how these techniques could help clean energy development break through the commercial viability barrier through removing historical biases and designing a purpose built delivery system to optimize cost and schedule and improve delivery predictability.

The concept of first principles thinking dates back to ancient philosophy. Aristotle was the first to formally describe it in his work Metaphysics, where he defined first principles as “the first basis from which a thing is known. [2]” These are truths that are self-evident and cannot be deduced from anything else.

First principles thinking is a structured problem-solving approach that breaks down complex challenges into their most basic, fundamental truths, known as first principles, and uses these truths as the foundation for building innovative, assumption-free solutions [3].

In modern times, first principles thinking has been applied in engineering, science and business by leaders such as Elon Musk, who credits the approach for enabling disruptive innovation at Tesla and SpaceX. Musk described first principles thinking as the process of “boiling things down to the most fundamental truths and reasoning up from there. [4]”

Rather than relying on analogy or historical precedent (“this is how it’s always been done”), first principles thinking forces a deeper analysis of the problem space by identifying the core elements that are objectively true and reconstructing a solution from the ground up. This method is particularly effective for solving novel or complex industrial challenges where traditional approaches fall short.

In the context of complex systems engineering or large-scale project delivery, first principles thinking offers several benefits:

To apply first principles thinking effectively, the following steps can be used:

Begin by articulating the problem in precise terms. Clarity at this stage is critical to avoid solving the wrong problem.

Deconstruct the problem into its basic elements—facts that are indisputably true. Eliminate assumptions, analogies, or inherited constraints.

Consider physical, technical, financial, or time-based constraints. Identify what resources are truly available and what limits are non-negotiable.

Ask “Why?” repeatedly to get to the root of each component. Identify areas where conventional thinking might be limiting better outcomes.

Using the identified truths, construct a solution that makes logical sense given the actual facts - not based on what has been done before.

Implement and validate the new solution, learning and iterating as needed. This phase ensures the approach is both practical and effective.

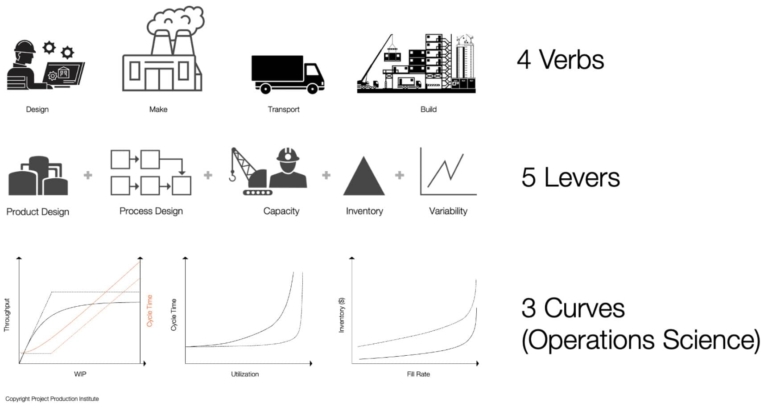

Rather than relying on conventional project management paradigms such as the iron-triangle and maximizing labor productivity, etc., Project Production Management (PPM) enables projects to be delivered faster, cheaper and with less cash tied up by viewing projects as an amalgamation of production systems. PPM leverages on four verbs – five levers – three curves (Operations Science) to map, model, analyze, simulate, optimize, control, and improve said production systems [5]. Rather than pursuing labor and equipment productivity in an attempt to improve project cost and schedule, PPM allows organizations to determine an appropriate trade-off between the five levers according to their business and project objectives using Operations Science. For more details, readers are advised to read “Built to Fail: Why Construction Projects Take So Long, Cost Too Much, and How to Fix It” by Zabelle and visit Project Production Institute (www.projectproduction.org).

This paradigm shift, supported by a scientific approach to design/configure and control a production system, has enabled organizations to experience 10-30% cost and schedule reduction, 30-50% cycle time reduction, and 300% better predictability, while providing upstream and downstream visibility that so many project teams are desperately seeking [5].

To improve any system, the system itself has to be clearly defined and understood. If a system is expressed in such a way that obscures the true behavior of the system and misrepresents the variables that drive such a behavior, any solutions and the approaches to managing that system will very likely be ineffective.

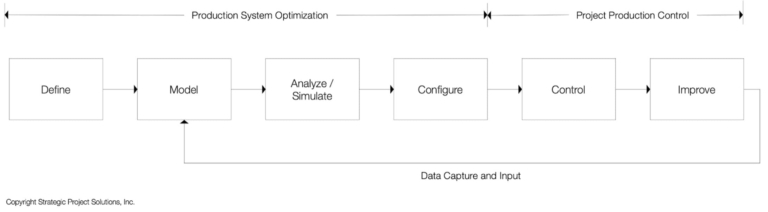

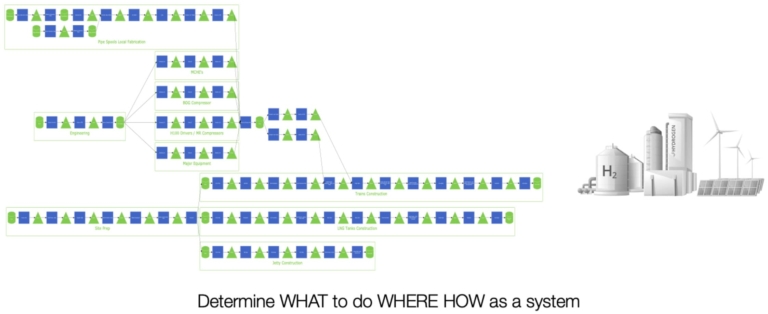

Specifically, the PPM implementation process (Figure 2) enables organizations to answer two critical questions: (1) how do we want the production systems to behave, and (2) how do we ensure the production systems behave the way we intended to deliver the project's business objectives successfully. The process for answering the first question is known as Production System Optimization (PSO), and the process for answering the second question by operationalizing the answers to the first question is referred to as Project Production Control (PPC). The two approaches are iterative. Simply put, PSO provides the production guidelines and policies to control the production system for PPC, whereas PPC provides the data to understand the actual behavior of the production systems and areas for improvement for PSO.

Production systems that are not yet operational should begin with PSO, and those that are already operational MAY begin with PPC as a means to capture actual data if it doesn’t exist yet.

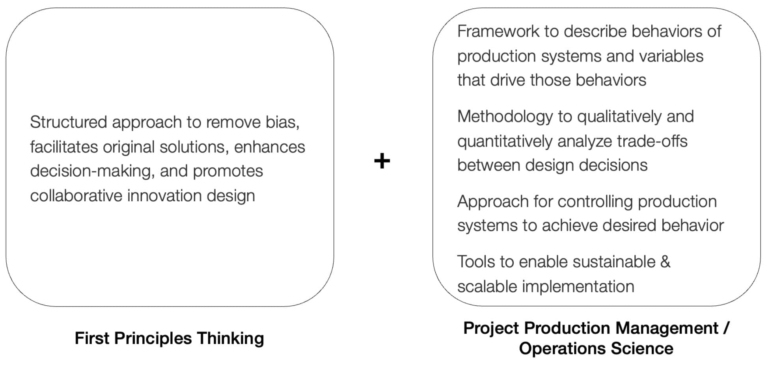

The goal of combining these two approaches is not merely a thought exercise but necessary to deliver novel solutions that deliver breakthrough performance for businesses and the broader economy. First Principles Thinking brings a Structured approach to remove bias, facilitates original solutions, enhances decision-making, and promotes collaborative innovation design. In contrast, Project Production Management / Operations Science brings a framework to describe behaviors of production systems and variables that drive those behaviors, a methodology to qualitatively and quantitatively analyze trade-offs between design decisions, an approach for controlling production systems to achieve desired behavior and tools to enable sustainable & scalable implementation (Figure 3). Since Operations Science applies to any form of operations, it can be used to design the solutions (assets) themself as well as the “project” production systems used to deliver these solutions (assets).

The first step for applying First Principles Thinking (FPT) is to clearly define the problem, establish the desired outcomes, and break the challenge down into its fundamental truths. Similarly, the first step in Production System Optimization (PSO) is “define,” which involves producing the Basis of Production System Design that captures the purpose, objectives, and performance requirements. Once the business and production objectives are clearly defined, the design of the production system can begin.

At this stage, it is critical to develop a “model” that outlines the product and the process that will enable outcomes to be achieved. It is critical to understand what the “product” is. For example, the product for a renewable energy solution is “energy” measured in MWs. The product for the project is an “asset” which will be used to deliver the energy. This stage is where there is a significant risk of traditional solutions infiltrating for the “product” as well as the “project”, setting the foundation for all subsequent steps while reducing the potential value a solution can deliver. It is essential to challenge every perceived limitation that has led to the traditional solution through the application of FPT, whether these limitations are based on technology, timelines, supply chains, etc. A good example of coming up with innovative solutions to break underlying assumptions is creating a type of glass that did not exist at the time of Steve Jobs’ iPhone announcement at MacWorld, and then scaling it to produce millions of iPhones in a matter of months. The possibility of achieving this is so outrageous that this phenomenon has a name called “Steve Jobs’ reality distortion field.” He is also well-known for avoiding the use of focus groups when developing products, thereby preventing the stifling of innovation. This clearly demonstrates how important it is to set the objective clearly and not limit the solutions based on preconceived existing solutions.

Once the product and process (among the five levers) are determined at a high level, OS can be used to determine what labor, equipment, and space are needed to achieve the required throughput (demand). The product and process most often have to be adjusted based on the potential solution for capacity, inventory, and variability. This is critical since there are no free moves within the five levers, i.e., when a lever changes, one or more other levers change regardless of whether it is intentional or unintentional.

While this phase will naturally involve a high degree of variability due to the innovative nature of the problem-solving, it can be modeled and incorporated into system dynamics to help define optimal production control policies (including work-in-process levels) and determine effective control mechanisms. Once the process system is modeled, scenarios can be simulated to evaluate different paths, allowing the businesses to select the approach that best aligns with their goals and constraints.

Although it may seem counterintuitive to invest critical time upfront in planning an innovation phase, this step ensures that teams are properly resourced, have the necessary tools, and operate against a realistic and robust timeline. It also helps manage team utilization, minimize burnout, and support clear communication of progress to leadership. If leadership challenges the team to accelerate delivery, the model can objectively illustrate the impact, highlighting whether such a request would hinder progress and what trade-offs or additional resources would be required to accommodate it.

This complementary interaction ensures that innovation is grounded in physical and economic reality, while execution is optimized to achieve sustainable outcomes.

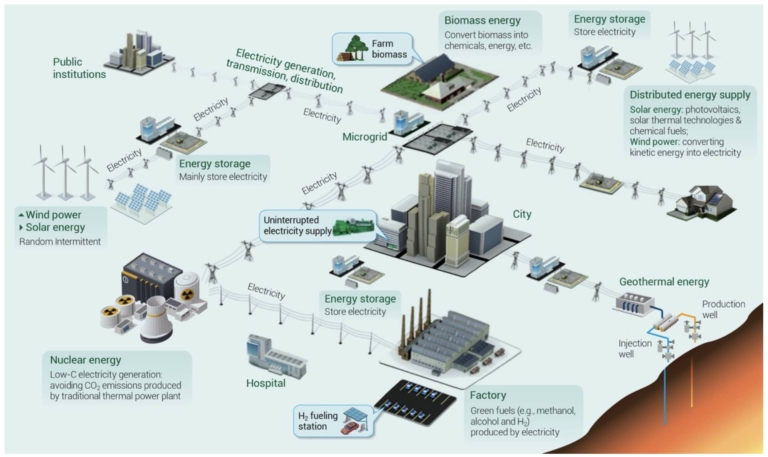

The world is standing at an inflection point in its pursuit of renewable energy systems. We have built solar panels that turn sunlight into electricity and wind turbines that harvest the kinetic energy of air. We have tapped rivers, the Earth’s core, the ocean’s tides and waves, and even the atom itself to generate power. Figure 4 depicts numerous existing technologies are available for renewable energy production. But despite this arsenal of clean technologies, a fundamental issue persists: carbon-neutral power is often unreliable and frequently expensive.

At the heart of the problem are two interwoven challenges—intermittency and competitiveness. Solar power only works when the sun shines. Wind turbines turn only when the wind blows. These natural rhythms don’t always align with our energy demands, especially in industries that require consistent, round-the-clock electricity. Battery Energy Storage Systems (BESS), most commonly based on lithium-ion technology, are often used to smooth out these supply gaps. But lithium batteries are costly, rely on rare earth materials and introduce both scalability and geopolitical concerns. Compounding the issue, renewable energy systems must often be oversized, sometimes by a factor of two or more, to power their loads and simultaneously charge these batteries. That overbuild drives up the cost even further.

Green hydrogen is by no means superior in all applications compared to geothermal, wind, and solar energy. However, it has unique advantages in the ease of energy storage, transportability, and high-temperature industrial use [15]. Despite growing interest due to this reason, the majority of green hydrogen projects remain commercially unviable without significant government subsidies. These projects are capital-intensive, high-risk, and span multiple years, making them vulnerable to the fluctuations of political cycles. A change in administration often brings shifts in energy policy, creating uncertainty for long-term investments. For green hydrogen to become a reliable component of the global energy mix, it must achieve cost parity with fossil fuel alternatives [6].

While not technically complex, green hydrogen projects present significant commercial complexity, from sourcing renewable power to securing off-take agreements. The traditional capital value process used in the oil and gas industry was built around technically challenging projects like deepwater developments or reservoir engineering. These processes prioritize extensive technical front-end loading, but they do not address the commercial intricacies that dominate clean energy projects. Green hydrogen demands a new development process that balances both technical execution and commercial strategy.

Electrolyzer technology presents another major constraint. Current units, typically around 60% efficient, were designed as standalone systems with their own control, cooling, and separation infrastructure. Scaling up by combining multiple units introduces redundancy, increases system complexity, and raises both capital and operational costs [7]. Existing designs are ill-suited for large or giga-scale deployment. To improve viability at scale, electrolyzer systems must be reengineered for integration, modularity, and cost efficiency.

Lastly, the intermittency of renewable power, particularly solar and wind, poses a fundamental challenge. A green hydrogen plant requires a constant and predictable power supply to maximize the efficiency and production of the plant. Addressing intermittency typically involves purchasing renewable electricity from the grid at a premium for a constant supply or overbuilding on-site renewable generation, often doubling capacity and adding battery storage. Both approaches significantly increase capital and operational expenditures. To unlock green hydrogen’s potential, the industry must develop cost-effective strategies to ensure power availability, minimize overbuild, and reduce dependence on grid-delivered energy.

An effective energy solution must have not just effective generation, transmission, distribution, or consumption, but a solution that optimizes the end-to-end value stream. Having sufficient generation capacity without sufficient transmission capacity, or vice versa, results in wasted time and money.

So how do we resolve this? The answer lies not in any single technology, but in a fundamental shift in how we design power systems. We must stop treating each source as a siloed solution and begin weaving them together into hybrid architectures, systems that combine the strengths of different technologies to compensate for each other’s weaknesses. Therefore, OS should be leveraged to design the right capacity for generation, transmission, distribution, and consumption.

Imagine pairing a solar farm with a nuclear power plant. Large-scale nuclear plants today often generate more electricity than is needed at night, leading to energy curtailment. That excess, low-cost power could be diverted to green hydrogen production facilities co-located nearby. During the day, solar takes over, feeding both the grid and the electrolyzers. The battery system that would traditionally be required to cover nighttime demand shrinks dramatically or is eliminated altogether. It’s a symbiotic relationship that leverages the baseload dependability of nuclear with the daytime abundance of solar.

This vision becomes even more compelling with the advent of Small Modular Reactors (SMRs) and microreactors, new classes of nuclear technology designed for rapid deployment, smaller footprints and load-following capabilities. These reactors can form the stable backbone of hybrid systems, flexibly ramping alongside renewables to maintain a consistent power supply.

The role of batteries, too, must evolve. Rather than defaulting to lithium-ion, we can reimagine storage in more elemental terms, storing heat instead of electrons. Rondo Energy has developed an Electrified Thermal Energy Storage. The Rondo Heat Battery uses inexpensive refractory bricks heated to over 1,100°C to store energy [8]. This thermal energy can then be used to produce steam and ultimately electricity, offering a resilient, low-cost storage solution made from abundant materials. It’s not just a different battery, it’s a different paradigm.

Meanwhile, innovators like Exowatt [9] are challenging the solar status quo entirely. Instead of converting sunlight to electricity using photovoltaics, Exowatt uses lenses to concentrate sunlight onto a heat battery, again storing energy as thermal rather than electrical. This allows for dispatchable, around-the-clock power delivery without relying on rare earth materials, significantly reducing both cost and supply chain risk. By avoiding the inefficiencies of PV-to-battery-to-grid conversion, Exowatt’s systems can deliver electricity in the range of $0.01–$0.04/kWh, well below traditional PV+BESS solutions.

Even hydroelectricity, long thought to be bound by geography, is being reinvented. Take Hydrostor’s A-CAES (Advanced Compressed Air Energy Storage) [10]. Instead of relying on existing salt caverns, their technology stores compressed air in engineered rock caverns, using water as a pressure-balancing mechanism. Heat generated during compression is captured and reused during discharge, enabling efficient, emissions-free energy delivery. With discharge durations of 8–24 hours and a projected system life of over 50 years, Hydrostor offers a long-duration storage solution that’s durable, flexible and remarkably low-cost.

The ocean, too, offers untapped synergies. Floating wind farms, now pushing into deeper waters, access stronger and more consistent wind resources. But what if these platforms could also host tidal turbines beneath them or capture wave energy as part of the motion compensation system? Such hybrid marine systems could create resilient, high-capacity baseload generation in areas where traditional infrastructure would never reach.

The right answer will vary by geography, resource availability and industrial demand. Employing OS to design an end-to-end production system and using the five levers helps to ensure that the optimal solution is identified at the start before significant engineering hours have been expended. But the process is the same, design the system backward from the economics, not forward from the technology. The era of energy abundance will not be unlocked by any one breakthrough but by how we choose to combine, iterate and scale the breakthroughs we already have.

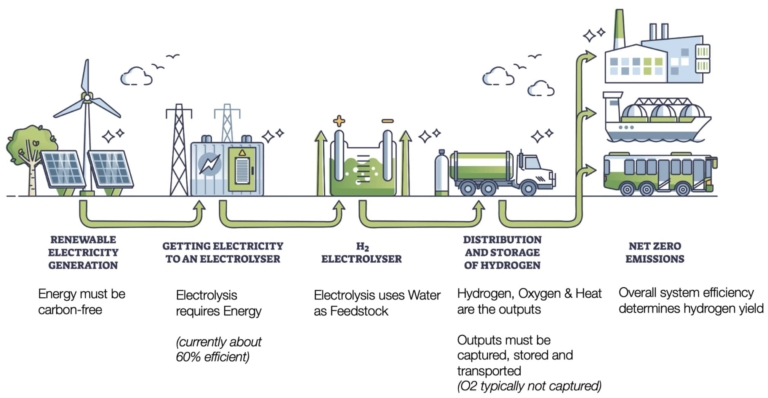

Using first principles thinking to analyze the full green hydrogen value chain from energy generation to end use, the following foundational truths emerge (Figure 4):

Green hydrogen must be produced using renewable or zero-carbon energy sources to maintain its environmental integrity.

Electrolysis, the process at the core of green hydrogen production, requires significant electrical energy to separate water into hydrogen and oxygen.

Purified water is a non-negotiable input. The quality, availability and treatment of water directly impact system performance and cost.

The electrolysis process produces hydrogen as the desired product, oxygen as a byproduct and heat as a form of waste or potential co-product.

The greater the system’s overall efficiency, the more hydrogen can be produced per kilowatt of input energy, making efficiency a key lever for commercial viability.

Rethinking must start with a question, what is the target cost of energy based on the desired Levelized Cost of Hydrogen (LCOH)? From that anchor point, we can evaluate various options regarding “what to do where how” that will deliver the desired outcomes derived from FPT (Figure 5).

Electricity makes up nearly half of the LCOH, the success of green hydrogen hinges on accessing clean power that is not only carbon-free but also cheap and dispatchable. Therein lies the paradox, clean power is plentiful, but not when and where we need it most.

Renewable energy assets such as solar, wind, hydroelectric and others are traditionally located where environmental conditions maximize generation efficiency. High solar irradiance, consistent wind profiles and adequate water flow are key criteria. These optimal conditions, however, often occur in remote or land-constrained regions. Moreover, utility-scale renewable projects require extensive land footprints which limits the number of viable sites even further.

This geographic mismatch between ideal renewable energy locations and safe, practical sites for hydrogen production introduces significant complexity. Bridging this gap often necessitates the construction of long-distance transmission infrastructure resulting in additional capital expenditure, extended project timelines and transmission losses. These losses not only degrade system efficiency but also require renewable energy systems to be oversized to compensate, further inflating development costs and energy waste.

Hydrogen’s physical properties present significant logistical and engineering challenges. As a molecule, hydrogen is highly volatile and difficult to store or transport in its gaseous state which has substantial implications for facility siting and infrastructure planning. For these reasons, hydrogen is frequently converted into more stable derivatives such as green ammonia to facilitate safer and more cost-effective transport.

Pressurized hydrogen storage must be located at a safe distance from population centers due to explosion risks. Electrolyzer technologies currently available are not optimized for giga-scale deployment and viable subsurface hydrogen storage options, such as salt caverns, are geographically limited and often located far from generation or consumption centers. Grid infrastructure upgrades are typically required to accommodate large-scale hydrogen production, adding yet another layer of complexity and cost.

The prevailing assumption in the industry is that green hydrogen and ammonia production must be land-based, constrained by the limitations of existing technologies and infrastructure. However, this assumption warrants re-examination. A shift in perspective toward offshore production could unlock substantial benefits and mitigate many of the constraints described above.

Co-locating hydrogen and ammonia production with offshore renewable energy, particularly offshore wind, offers a number of compelling advantages. By generating power behind the meter, such systems can eliminate the need for extensive transmission infrastructure. Proximity also reduces electrical losses and simplifies integration. Moreover, the vast availability of offshore space alleviates many siting constraints and enhances public safety by distancing production from population centers.

This offshore model draws inspiration from practices in the offshore oil and gas sector, particularly the use of Floating Production, Storage, and Offloading (FPSO) units. Applied to the green hydrogen economy, an analogous concept could involve offshore ammonia production platforms and subsea hydrogen production systems. This novel offshore model could be a crucial enabler for unlocking the commercial viability of green hydrogen at scale, such as the one being built in Shandong province, China [11]. SwitcH2 is also one of the pioneering companies in the development of offshore green hydrogen and ammonia production. SwitcH2 BV is a project development company, engineering and operating the next generation of offshore floating production systems for the delivery of green hydrogen and green ammonia for industrial offtakers [12]. SwitcH2 BV leads the charge in offshore green energy production through the design, construction, and operating a 300MW electrolyzer and ammonia synthesis unit on an Offshore Floating Production Storage and Offloading Unit (FPSO).

Several technical benefits further support the production of green hydrogen subsea. Ambient deep-sea temperatures (~4°C) offer passive cooling for electrolysis systems, eliminating the need for water-intensive cooling towers and thereby simplifying system design. Hydrostatic pressure naturally compresses the hydrogen produced during electrolysis which can reduce or eliminate the need for mechanical compression systems. This also leads to smaller gas bubbles at the electrolyzer membrane interface, improving gas separation efficiency and overall electrolyzer performance.

Locating production systems offshore reduces the requirement for aboveground infrastructure and significantly lowers the exposure of personnel to explosion risks. Modular floating or subsea systems can be standardized and deployed globally, minimizing variability and enabling the production system to be further optimized increasing productivity while reducing cost, time and cash resulting in improved competitiveness of green hydrogen. Offshore and subsea offers a scalable solution unconstrained by land availability or population density.

By reassessing through a first-principles lens, it becomes evident that offshore and subsea hydrogen and ammonia production can address many of the limitations faced by traditional land-based systems. Rethinking the location and integration of renewable energy and hydrogen production infrastructure opens a new frontier in the energy transition. Offshore and subsea systems, informed by decades of experience in offshore energy production could provide a safer, more efficient and more scalable pathway to realizing a global green hydrogen economy.

Renewable energy and clean fuel projects differ from traditional capital projects in several key ways:

By using FPT to challenge technical and commercial assumptions and PPM/OS to design the Green Hydrogen Solution and using PPM/OS to optimize and control the delivery of Green Hydrogen solutions, the following opportunities can be explored:

In addition, further benefits can be realized during the operations by leveraging FPT and PPM together:

For clean energy solutions, whether electricity, green hydrogen or green ammonia to become viable alternatives to fossil fuels, they must achieve cost parity without relying on government subsidies. Reliability, scalability and economic competitiveness are non-negotiable if these technologies are to be widely adopted into the global energy mix.

Current technologies, while proven at smaller scales, are not fit-for-purpose when applied to giga-scale clean energy projects. Key components must be fundamentally redesigned to support both scale and system-wide efficiency improvements. Without this, clean energy alternatives will struggle to compete in an increasingly cost-sensitive energy market.

By applying First Principles Thinking (FPT) in combination with Project Production Management (PPM) and Operations Science (OS), project teams gain a structured yet adaptable framework to question existing assumptions, define the most effective technology pathways, and implement them with precision. Clean energy projects require a new approach, one that recognizes their unique commercial and technical complexities. Purpose-built delivery models are essential to managing the ultra-low margins and high risks inherent in these developments, ensuring they are executed both efficiently and sustainably.

[1] IEA (2021) Net Zero by 2050: A Roadmap for the Global Energy Sector, International Energy Agency

[2] Aristotle (350BC) Metaphysics, ca. 350 BC

[3] Musk, E. (2012) Interview with Kevin Rose

[4] Vance, A. (2015) Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic Future, Harper Collins, 2015.

[5] Zabelle, T. (2024) “Built to Fail: Why Construction Projects Take So Long, Cost Too Much, and How to Fix It”, Forbes Books

[6] Hydrogen Council (2023) Hydrogen Insights 2023

[7] International Renewable Energy Agency (IRENA) (2020) Green Hydrogen: A Guide to Policy Making

[8] Rondo Energy (2025) “How It Works – Rondo Heat Battery”

[9] Exowatt (2024) “Thermal Batteries: Revolutionizing Solar Power,” White Paper

[10] Hydrostor Inc (2025) “Technology – Advanced Compressed Air Energy Storage”

[11] Collins, L. (2025) “World’s first offshore platform to produce green hydrogen, ammonia and methanol completed in China”, Hydrogen Insight, 15 April 2025 https://www.hydrogeninsight.com/innovation/world-s-first-offshore-platform-to-produce-green-hydrogen-ammonia-and-methanol-completed-in-china/2-1-1808095

[12] SwitcH2 BV (Feb 2025) “SwitcH2 Welcomes New Shareholder JORD Group”

[13] Wang, F (2021) “Technologies and Perspectives for Achieving Carbon Neutrality”, Innovation (New York, NY)

[14] Murphy Jr., Bill (2025) “Steve Jobs Forced a Big iPhone Change That Nobody Thought Was Possible. Here’s How He Did It and Why It’s Better” Inc. Newsletter. https://www.inc.com/bill-murphy-jr/steve-jobs-forced-a-big-iphone-change-that-nobody-thought-was-possible-heres-how-he-did-it-and-why-its-better/91168331

[15] International Energy Agency (IEA) (2025) Website. https://www.iea.org/energy-system/low-emission-fuels/hydrogen