The future of capital project execution for the heavy industrial sector needs to look at innovative ways to improve productivity and project success, which includes the implementation of productization methods. The benefits of a productization strategy are not well known, however industrial productization is becoming more communicated within the industry as the future implementation model. Industrial productization utilizes more of a manufacturing style approach to not only improve productivity but to reduce overall lifecycle costs and schedules and improve overall quality and safety.

Industrial productization combines modularization and standardization methodologies, to take advantage of repeatable components, equipment and facilities to reduce non-value add execution and design waste. Companies need to develop a business case to productize to ensure that the supports the use of the optimum amount of both modularization and standardization, captures the business drivers and benefits and to align the program teams with the productization strategy.

This paper will discuss the requirements and timing that companies will need to develop an effective productization business case that will complement the overall project business drivers.

Keywords: Productization, Standardization, Modularization, Modular Construction, Modular Design, Offsite Construction, Offsite Assembly, Project Management, Program Management, Capital Projects

Cathy is the Vice President of DyCat Solutions Inc., a company which provides innovative solutions to the heavy industrial business sector. Cathy facilitates workshops and alignment sessions with customers using DyCat’s four innovative solutions: Modularization, Facility Standardization, Lean Design and Execution. These solutions enable the ability ...

The future of capital project execution for the heavy industrial sector includes the implementation of productization methods. The benefits of a productization strategy are not well known, however industrial productization is becoming more communicated within the industry as the future implementation model. Industrial productization combines modularization and standardization methodologies, to take advantage of repeatable components, equipment and facilities to reduce non-value add execution and design waste. Companies need to develop a business case to productize to ensure that the supports the use of the optimum amount of both modularization and standardization, captures the business drivers and benefits and to align the program teams with the productization strategy. However, owners, engineers and constructors may not necessarily understand how to develop a business case which supports the use of industrial productization and the proven benefits on their projects.

Industrial Productization is the future of heavy industrial construction projects. This new design build method addresses most owner’s strategies of the future:

Productization can be defined as “the process of analyzing a need, defining and combining suitable elements, into a product-like object, which is standardized, repeatable and comprehendible” [1]. Industrial Productization is defined as the process of designing and building one process facility, or sections of a facility that can be replicated for all other similar types of facilities or sections of facilities. It is intended to reduce the business risk for the program or project as the business can break the facility down into “bite-sized pieces”. Industrial productization combines lean design and execution methods, with standardization and modularization. Examples of industrial productization include data centers, renewable natural gas plants, Liquified Natural Gas (LNG) trains, micro/small/ medium scale LNG plants, hydrogen plants, carbon capture plants, air separation units, sulfur plants, small scale nuclear plants, oil and gas well facilities and natural gas plants.

To develop an effective business case, the first step is to fully understand the benefits a productization can bring to your company. The following is an overview of the benefits that productization can bring to a company:

When a company is deciding to implement productization methods on their facility or section of the facility, a business case will need to be developed to support the decision to productize. Also, the timing of when you perform a business case analysis and make the decision to productize is extremely important. This paper will discuss the requirements and timing that companies will need to develop an effective productization business case for a heavy industrial facility or section or a facility.

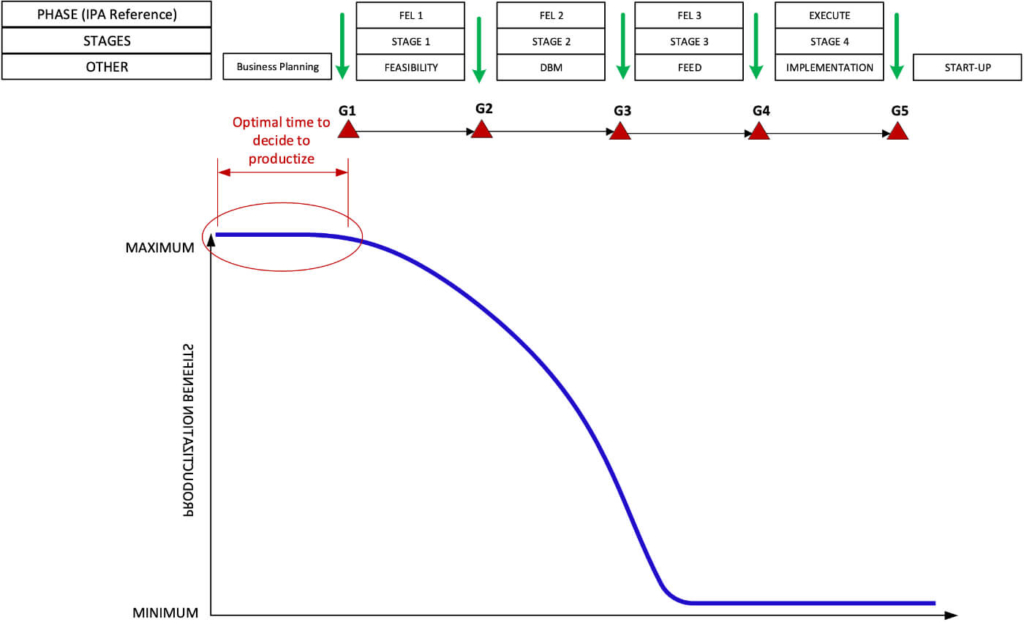

The decision to productize all or part of the facility needs to be made earlier in a project lifecycle, typically before the FEL-1 phase begins. Figure 1 based on the UMM-001 research [3] and RT-283 Best Practice [2] from the Construction Industry Institute, illustrates the optimum timing to determine whether productization is the correct strategy and as the figure illustrates the optimum time is no later than the start of FEL 1 phase. If the decision to productize is made later in a project lifecycle, it will reduce the amount of productization opportunities and benefits the program or project will realize.

Implementing productization requires many early planning requirements that include the development of the standardization and modularization program execution and design strategy to ensure the success of the product development and execution. The business case analysis will need to be performed to make the decision to productize and should be completed in the business planning phase of a program or project.

To perform an effective productization business case analysis, you will need to define or perform the following elements:

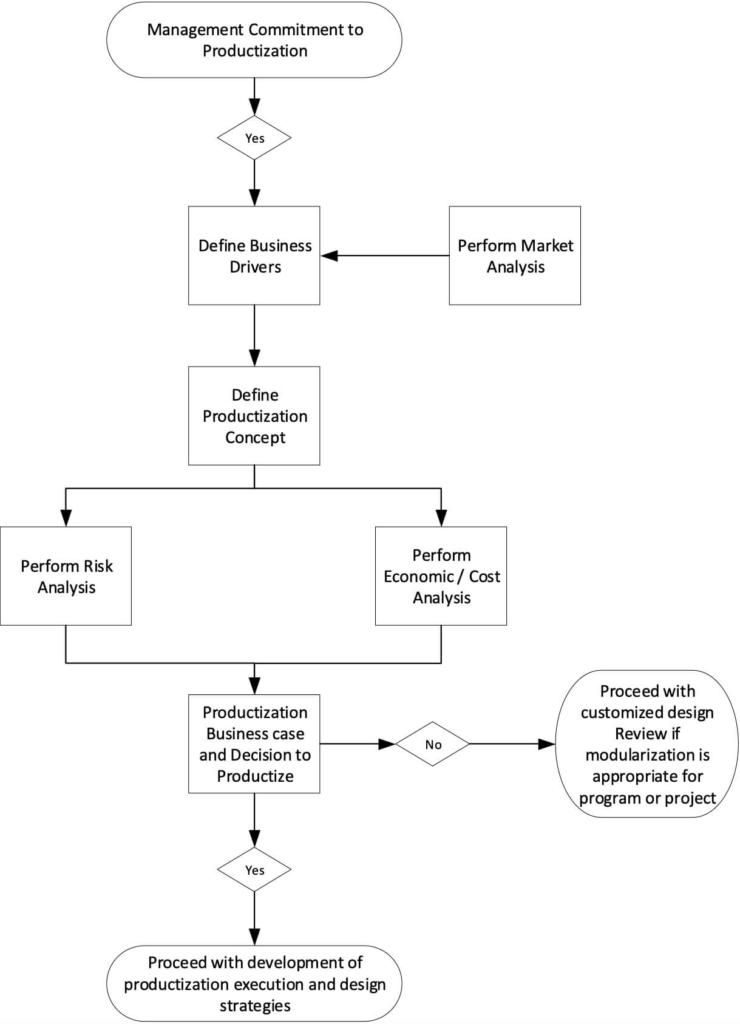

Figure 2 below illustrates the workflow that can be used to decide to productize and develop a

business case.

The first question in the workflow is “Does the facility or section of a facility have commitment from management to productize?”. The company’s executive management team must be committed to exploring and / or defining productization for a specific facility or section/unit within a facility. A successful implementation of productization for an industrial facility or section of facility requires support, methodology buy-in, and productization champions, including approval roles and responsibilities and promoting a culture of productization acceptance. There must be a clear level of organizational support and corporate responsibility, with a visible and ranking management champion. The corporate culture for the productized facility or section of a facility will need a program or product development team that understands both the modularization and standardization methods that will be utilized on the execution and design to maximize productization benefits. The productization business case will allow management to make an informed decision to productize and the factors that the decision was based on. The business case is intended to be utilized as an alignment tool for the program or product development team throughout the life cycle of product development.

After understanding the benefits that an effective productized execution and design can bring to a productized facility or section of a facility, it is easier to understand the productization business drivers. A market analysis should be performed on the product before defining the program or project business drivers. It should focus on the market demand, capabilities of the supply network and the competitors already in the market. The market analysis should define the size, volume, capacity, and scope of the project under consideration to productize. The analysis would also determine when and where the product in facilities would be built and the market risk to implement productization for the specific facility or units. After the market analysis is completed, the productization business drivers can be determined.

Understanding and aligning on the productization business drivers at the beginning of the program or project and throughout the project life cycle with the stakeholders is extremely important for the success of the program or project and ensuring an effective decision to productize. The following list are proven business drivers that should be considered when developing a productization business case:

The main business drivers to implement productization on your program or project should be defined and included as part of the business case to productize.

The productization concept needs to be defined on what and how much can be standardized and modularized for the program or project based on specific market and project factors. To assist developing the productization concept the following factors will need to be defined:

Productization combines both standardization and modularization. The modularization concept needs to be defined on what and how much can be modularized for the project based on specific project factors including what is available through supplier led solutions. This will become the basis of the product design parameters for the different standard modules that may make up a facility. To assist developing the module concept the following factors will need to be defined:

The module concept will need to be reviewed for all possible site locations, to ensure a module size is chosen that will accommodate any constraints the sites may have. To define the module concept and modularization strategy, the following elements will need to be documented regarding the site data:

Modular execution requires access to the site from land and/or water to support the transport of modules from the module fabrication and assembly yard to the plant site. Understanding site access for all potential site locations is critical to determine the degree of modularization that can be supported. In addition, review of the module fabrication and assembly facilities(s) will need to be analyzed and understanding of the contractors’ capabilities will have an impact on the overall product execution. In order to effectively productize and maximize the benefits, long term relationships will need to be developed with the module contractor. In addition, the strategy for the location of fabrication vs location of assembly will impact the amount of inventory required and cycle time. All of these elements will impact what and how much a project can modularize and should be documented as part of the module concept.

Once the potential module fabrication and assembly yard locations are defined, the preliminary transportation route with options can be identified including the proposed site locations including global locations if the product will be marketed globally. Once this is completed, a preliminary module envelope size can be determined based on any transportation and logistics constraints along the high-level routes. Some transportation constraints include bridges and overhead power lines but can include more depending on if the site location is inland or by water. At this stage there will be a couple of route options depending on the site locations, and this will impact the amount of modularization that can be obtained for the product and become a productization key factor for the standard module design.

Each facility owner may have some technical constraints that could impact the amount of modularization that can be implemented for the product. These technical constraints are typically found in specifications that are not adapted to a productized facility. Some technical constraints include locating dynamic machinery on modules, the use of centralized or distributed electrical and controls and locating air coolers above other equipment on modules.

Even though these may be considered a constraint, they can be removed by working with the facility owner on updating their specifications to adapt to productized facilities or developing a technical deviation for the impacted specifications. Realizing these technical constraints early in the project lifecycle will allow the project to develop a plan on how to remove them to allow a more optimal product design and realize more benefits.

To effectively productize a facility or a unit within a facility, an understanding the following technical data will be critical to develop the product design basis:

When considering productization, the process technology utilized should be simple, flexible, mature, and repetitive. If the process technology is not proven and has a risk of process change in the detail engineering phase, then we would not consider utilizing productization until the process technology is proven. Ensure the technology has the flexibility to respond to production options and it can be scaled if required.

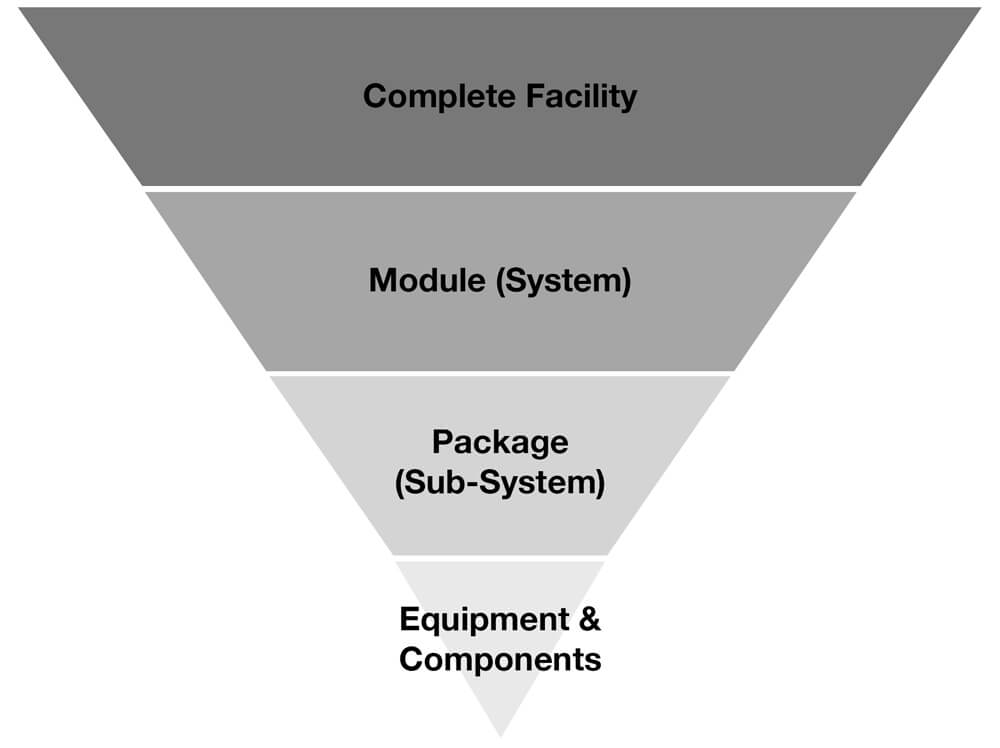

Facility standardization is the development and use of consistent designs and standards for repeatable projects within a program. There is a varying level of standardization that can be applied to a facility. The more standardization that is applied, the more the benefits will be realized. Figure 3 illustrates the levels of standardization:

There is not a one type “fits all” approach and each owner will need to review and apply the appropriate level of standardization that makes sense for the facility. The higher percentage of standardization, the greater the cost and schedule savings as well as other realized benefits. To fully productize, we would recommend the combined use of standardized modules or vendor packages. The decision on how many module or vendor packages will be standardized will depend on the complexity of the project and the ability to make duplicate identical or repetitive modules for an entire unit or facility.

When considering the productization of the facility or unit, the number of standard modules should be considered. The number should be based on the program or project duration and product lifecycle. The most economical for industrial productization is to ensure that the products are repeatable and can be used for other facilities or units without any customizations.

Understanding the benefits that productization can deliver and how this type of execution will support the business case is important. To support the business case a life-cycle cost analysis should be performed to justify why an owner would want to incorporate productization into their programs or projects. An effective way to provide a cost analysis is to compare a project productization to a traditional custom stick-built project to show the overall lifecycle savings.

To perform an effective cost analysis, the following factors or inputs will need to be defined:

Once you have all the positive and negative inputs you can generate overall cost savings compared to a traditional custom stick-built project. When evaluating the cost benefits of productization it is difficult to place an actual amount on some of the benefits such as:

These benefits can be subjectively quantified to support the business case. The amount of savings will depend on the site location and environmental/socioeconomic conditions.

The UMM-001- Standardization Business Case Analysis Tool from CII [1] provides a template to perform a cost analysis for standardization. It provides a means to evaluate the actual cost impact of productization decisions and can be used to provide a confidence factor.

Productization can reduce the overall program and / or project risk by standardizing the execution, engineering and design and moving the field labor from site to an offsite controlled location such as a module yard. As productization reduces the program and / or project risk, it also introduces some new risks. Understanding the productization risks and developing successful mitigation strategies is very important to the success of the execution of the product development.

Any new risks will need to be identified early in the project lifecycle and ensure there is a risk management and mitigation plan in place. The risk management plan should be reviewed as part of the overall productization business case in conjunction with the productization concept and cost analysis.

In conclusion, to effectively develop a business case for productization your will need to understand and align on the owners productization business drivers that support the business case, understand the site and technical considerations and constraints that may impact how much productization you can incorporate on your project, develop the productization concept and perform both a cost and risk analysis. Once these elements are defined, there will be sufficient data to decide if productization can be effectively applied to your program or project and what level of product is justified. It will also provide a business case for productization to executive management to make informed decisions.

The productization business case is a great tool that can be used to align the Owner business and program or project teams with the productization strategy and objectives at the beginning of a program or project. It can also be used as an alignment tool throughout the project lifecycle for EPC contractor project teams and as the program or project progresses aligning new team members with the overall business case and strategy to implement productization.