The construction industry faces a growing labor shortage, particularly in skilled trades, leading to increased costs and operational risks. Raise Robotics addresses this challenge with a modular robotic platform designed to automate high-risk, repetitive tasks on construction sites. By initially focusing on building envelope construction, the company demonstrated the value of its system in reducing schedule delays, cost overruns, and safety risks. Real-world deployments have validated its approach, with measurable time and cost savings reported by early partners like JR Butler. Built on a hardware-agnostic, perception-driven architecture, Raise’s platform supports a range of applications including layout, drilling, and fastening, with future expansions planned. This approach enables contractors to adopt automation without disrupting workflows, offering a scalable solution to workforce shortages while enhancing quality and safety across construction environments.

Keywords: Construction Robotics; Modular Automation; Workforce Transformation; Production System Optimization; Autonomous Systems; Real-Time Localization; Computer Vision In Construction; Labor Productivity; Multi-Functional Platforms; Jobsite Automation

Gary Chen is the CEO and co-founder of Raise Robotics. He leads company strategy, product development, and investor relations. With a background in robotics engineering and taking research to market, Gary is driving the company’s vision for scalable, autonomous systems that improve safety and efficiency across the construction industry. Before Raise ...

Conley Oster is the COO and co-founder of Raise Robotics, where he leads field operations, sales, and business development. Drawing on his experience in construction project management and crane & rigging sales, Conley bridges field needs with emerging robotics capabilities to deliver practical, jobsite-ready automation.

Finding workers has become a significant challenge for contractors worldwide. Although younger workers are beginning to enter the construction workforce, the labor shortage continues to grow faster than the rate of hiring [1]. The retirement of older workers has created a skills gap, where new workers often lack the experience and mentorship needed for highly specialized tasks [2]. These workforce challenges not only increase costs through rising wages but also introduce higher risks, as contractors struggle to maintain safety, quality, and schedules with an inconsistent labor supply.

Raise Robotics develops automation solutions to address this gap and reduce risk on construction projects. The company’s goal is to create a versatile robotic platform for a range of repetitive, quality-critical tasks on job sites. Designed to be user-friendly and easy to adopt, Raise’s robots help rapidly upskill the existing workforce while directly improving safety. By offering an alternative to manual labor, Raise aims to enhance productivity and safety while attracting a new generation of skilled operators and technicians to the construction industry.

Robotics development requires significant capital and time investment, making the selection of the initial use case an important decision. The application must be a pressing industry need and be repeatable across multiple customers.

Raise Robotics started with automation of tasks in building envelope construction for commercial projects. This area was ideal due to several factors:

|  |

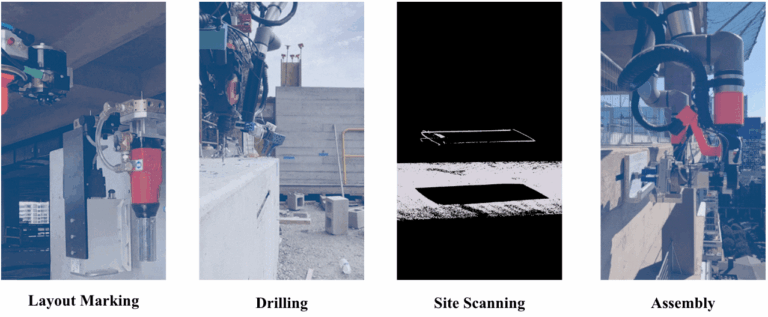

Construction of building envelopes is a complicated process and requires several individual tasks to be performed successively in sequence. Typically, the tasks can be lumped into three phases: layout, installation of anchors, and installation of panels. Each phase relies on the successful completion of the previous phase according to specification, but each phase is typically performed by a separate set of workers. As a result, mistakes in earlier phases often weren’t discovered until later in the process, requiring significant rework to fix the issues.

To address this problem, Raise Robotics decided to focus on the initial steps which could result in the highest risk and also consumed significant amounts of time: layout and installation of anchors. Being able to repeatably complete these two tasks to specification would remove most of the risk from the construction process while significantly accelerating schedule and saving on-site construction costs.

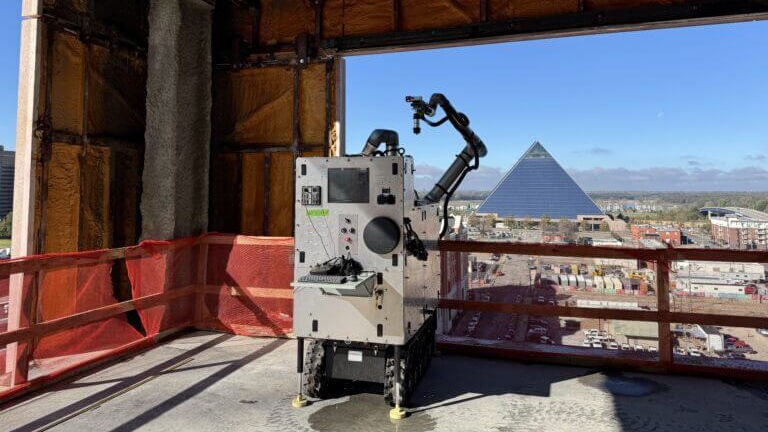

Today, Raise Robotics’ machines have been deployed for over 3500 hours in the field with no incidents and have been used on projects across the US. To accelerate market entry, the company partnered with a select group of customers who served as design partners. This allowed the team to remain focused while ensuring the product was delivering value. Once the product was ready to deploy, customers were able to immediately see savings.

JR Butler, a Colorado-based glazing contractor, was a key early partner in the development of Raise Robotics' platform. They worked closely with the Raise team during early testing and deployment, helping refine the system across multiple projects. This early collaboration resulted in significant schedule and cost savings during a production deployment on a healthcare project in Memphis, Tennessee, where manual layout errors on the first two floors had resulted in over $130,000 in rework. By using Raise’s robotic layout solution on the remaining floors, JR Butler achieved a 2-month reduction in schedule duration while significantly lowering operational costs through improved accuracy, reduced rework, and increased efficiency.

Strategic partnerships with its core group of adopters have enabled Raise to:

This collaborative, field-first approach has enabled Raise to transition from R&D to full-scale commercial use. The platform is now actively contributing to schedule certainty, quality assurance, and workforce efficiency across some of the most demanding construction environments.

With successful deployment of initial applications, Raise Robotics is now focused on expanding its robotic fleet and introducing additional capabilities for customers. Recent advances in software modeling and availability of low-cost sensors have opened the door to automating applications that were previously too complex and expensive.

Raise’s current system is a mobile manipulator with one or two 6-DOF robotic arms and interchangeable end effectors. Its modular software and hardware architecture enables reuse of individual components, such as end effectors, arms, perception models, and planning software, across multiple applications. This allows the system to be easily adapted to suit customer needs, while taking advantage of existing off-the-shelf devices, such as handheld concrete drills, industrial scanners, and more for shorter development times.

A key challenge in unstructured construction environments is perceiving and adapting to dynamic surroundings. Raise has developed a proprietary perception and planning system, leveraging synthetic data for training deep learning models and real-time motion planning for adaptability. Robots are cloud-connected, enabling data collection that improves future performance and provides customers with operational insights.

Today, Raise Robotics’ system supports layout, drilling, scanning, and fastening applications. Moving forward, the company plans to expand functionality by supporting additional applications such as caulking, welding, overhead anchor installations, and more. The company also aims to support additional access platforms, starting with integration of scissor lifts, enabling their machines to service the same set of applications in elevated conditions.

Raise Robotics allows contractors to integrating robotics without requiring fundamental changes to existing workflows, resulting in expert-level performance without the need for extensive training or specialized labor.

Raise Robotics has demonstrated that integrating robotics into commercial construction is both feasible and increasingly essential. By targeting high-risk, repetitive tasks with a modular, adaptable platform, the company has shown how autonomy can drive improvements in schedule performance, labor efficiency, and work quality. Its successful deployment in façade applications validates the technology and provides a repeatable foundation for expansion into additional scopes. With new tools in development and a software stack built for scale, Raise is positioned to become a transformative force in construction—augmenting the workforce and addressing the industry’s most urgent structural challenges.

[1] https://www.abc.org/News-Media/News-Releases/abc-construction-industry-must-attract-439000-workers-in-2025

[2] https://www.constructiondive.com/news/2025-workers-construction-needs-how-many/738205/

[3] https://ascelibrary.org/doi/abs/10.1061/%28ASCE%29LA.1943-4170.0000484