Target Value Delivery (TVD) is a process for setting project value targets and the corresponding cost targets prior to design, then steering design and construction to those targets. Doing so has proven to consistently deliver value for money. This paper describes how TVD differs from other project delivery processes and how to do TVD successfully.

Keywords: Allowable Cost, Construction, Steering to Targets, Target, Value

An accomplished educator, author and public speaker, Dr. Ballard is currently a member of the construction engineering and management program faculty at UC Berkeley. Glenn entered the construction industry in 1976 as a pipefitter’s helper on a petrochemical project in the Houston Ship Channel, moved from there to area engineer, then Manager of Produ ...

This paper is drawn from the book Target Value Delivery of Building Projects, which is to be published in 2023 by Cambridge Scholars Publishing. The book reports the findings of a Research Group formed in 2016 by UC Berkeley’s Project Production Systems Laboratory to describe and evaluate the effectiveness of Target Value Delivery (TVD). The book is being published to persuade the building industry to adopt TVD wherever feasible, and to strive to make it feasible where it isn’t, whether from laws or policies.

The book was limited to building projects because, with some exceptions, that is what is in the published literature. However, its authors believe that it is equally applicable to all types of construction projects and recommend future research to determine if we are right.

The focus in this paper is how TVD works in the design phase of projects. Topics covered include:

The key difference between TVD and other project delivery processes is setting project targets for value and the corresponding cost prior to design. Doing so requires better understanding what’s wanted and what that is worth to the project owner. If cost is to be set post-design, designers have no guardrails and are at greater risk of wasting time and money. Steering is reduced to trial and error.

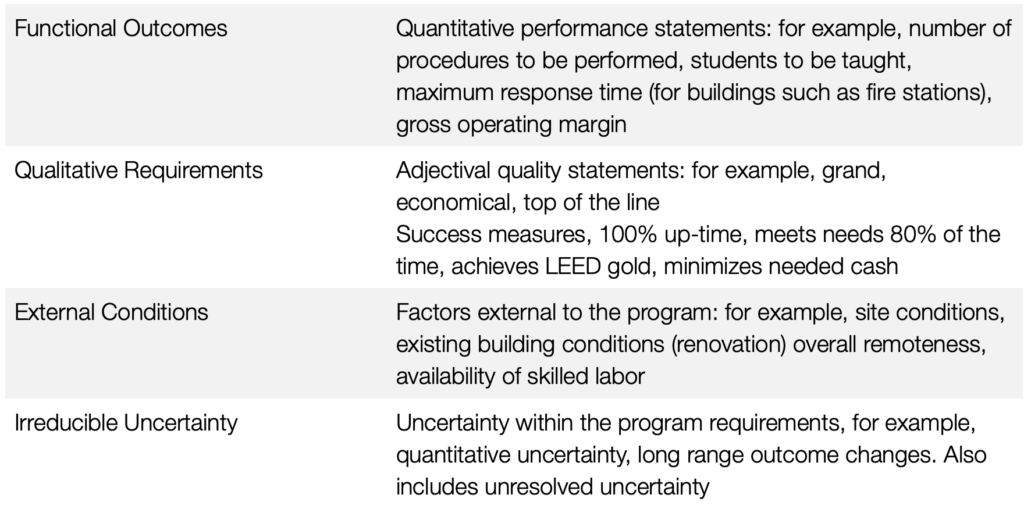

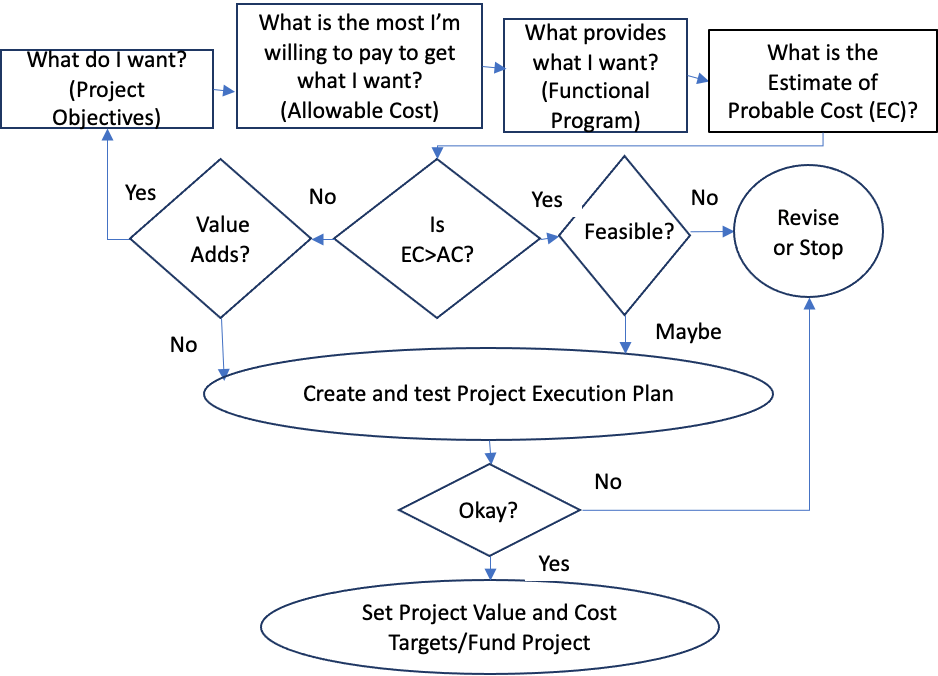

Target values are set in the project definition phase based on what’s wanted from the project. A given project might be launched to create a hospital in a certain location capable of treating a certain number of patients with certain medical conditions annually and generating a certain profit. Value targets are what are needed for achieving those objectives. An allowable cost is set based on expected benefits from hitting value targets—the most a client is willing and able to pay to get what they want from the project. The functional program shown below in Table 1 documents what’s wanted (functional outcomes and qualitative requirements) and also external conditions and irreducible uncertainty that must be managed in order to deliver those functionalities to qualitative requirements.

The estimate of project cost is made by creating a facilities program (see Table 2 below) capable of providing what’s wanted, then costing the services and materials in that facilities program.

This can be understood as creating a facility information model, but unlike such models used in the design process, this one has no visual read-out. The explanation for that is provided by the following quote from the TVD book, describing how the Haahtela Group in Finland does TVD:

What’s wanted (target value) and the cost of providing what’s wanted (target cost) are determined prior to design by creating through simulation a model of the building from the voice of the customer, then costing the materials, components and services needed to construct that building. The simulation model is fully detailed, buildable, and capable of supporting desired functions at desired capacities, but is not what will be constructed, leaving designers free to create designs that deliver target values within the target cost.

From Chapter 3

Haahtela uses a software they created that captures what a client says they want and provides a design solution that provides it. The estimated cost changes with every change in the model. Pricing of services and materials is done based on current costs for the project location and time, adjusted as needed for inflation/deflation. Several other such software programs were found by the TVD Research Group, including from AECOM, the Boldt Company, Building Catalyst, DPR Construction and Proctor and Gamble.

This movement from functional program to facility program is a type of regressive thinking which is also used in analysis of undesirable outcomes (errors, injuries, failures) in search of countermeasures to their reoccurrence. Regressive thinking usually proceeds by searching for known solutions both internal and external. When known solutions fail, abduction is used to create new solutions by constructing and testing hypotheses. The ability to improve performance through design, whether of product or process, depends to a great extent on the ability to abduct [1]. An example of a project whose value targets all required abduction is provided later in the section on Value Engineering.

Why have designers create a design once you have a building information model that delivers what’s wanted? Because 1) Indefinitely many designs can be created that support the functional program but with different costs. With the addition of contingencies as needed, costing the design implicit in the facilities program provides sufficient funds to deliver the functional program, but the needed funds can be reduced by creating alternative designs and 2) designers are freed to design not only for cost reduction, but also for value enhancement, both for features whose value can be quantified and more subjective features such as beauty, live-ability and architectural harmony with surroundings.

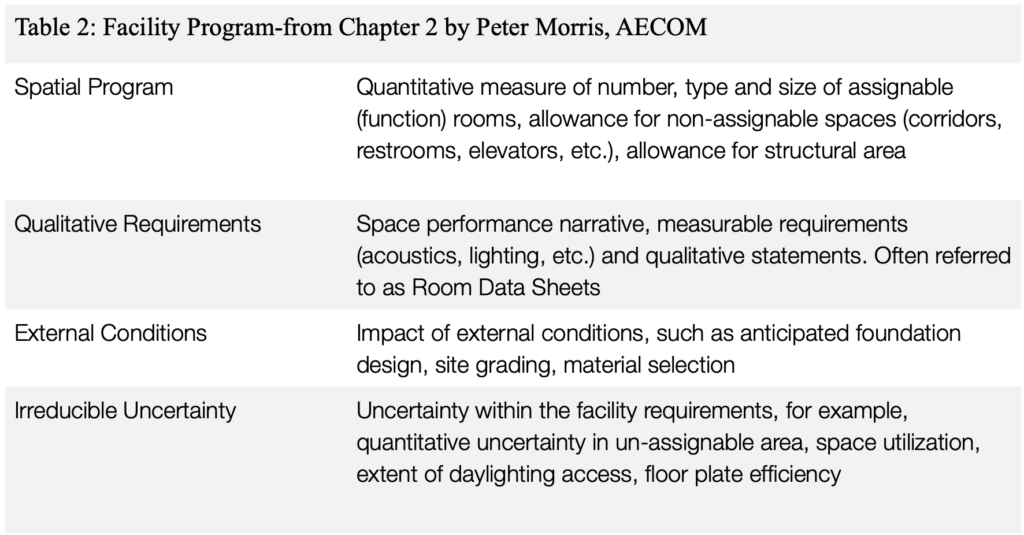

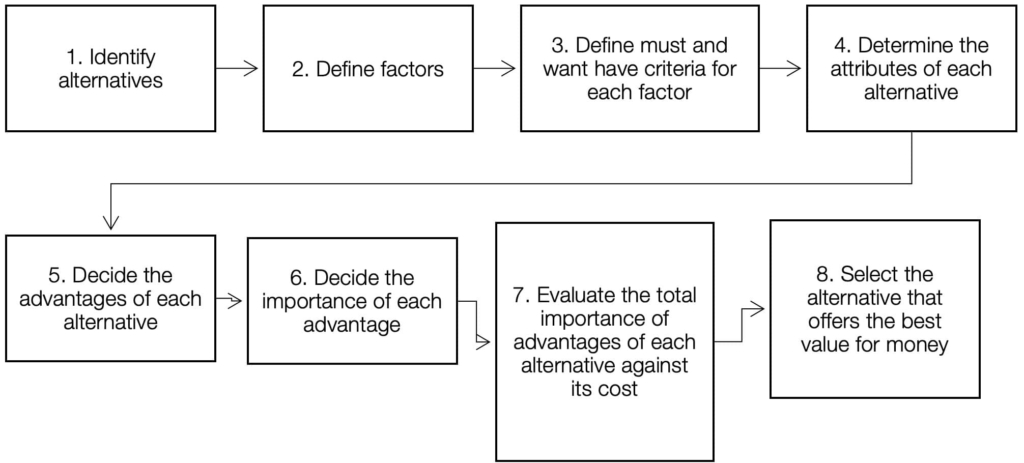

The process for getting to project value and cost targets is shown in Figure 1 below.

The first step is to determine the objectives of the project, then the project allowable cost (AC) and the functional program. As stated earlier, the facilities program is used to develop an estimate of probable cost (EC). If EC is greater than AC, the owner may choose to add to what’s wanted. If expected cost exceeds allowable and the gap is not considered feasible to close, the project objectives are revised or the project is killed. If the gap is considered feasible to close, a Project Execution Plan is created and tested until the level of risk is acceptable or the project is abandoned. If acceptable, project value and cost targets are set and the project is ready to be funded. On projects that share risk and reward between owner and those who deliver the project, this validation is done by both parties. Ultimately target cost is set equal to the expected or below (nb: all things else being equal, stretch goals are prudent when projects can afford the time and money for abduction).

Project execution plans typically include detailed schedules used to test alternative approaches to project execution. Once the project is approved, the master schedule is expressed in terms of major milestones and their intersections, leaving more detailed planning of phases and sub-phases between milestones to be done in accordance with the rules: plan in greater detail as you get closer to doing the work, and involve those who are to do that work in planning how to do it [3].

Once the project level target cost is determined, a Cost Plan is developed that provisionally allocates costs for facility systems to the cross-functional teams that design the project. I use the Boldt Company’s name: “Innovation Teams” for these cross-functional teams. Facility systems are the basis for allocation of cost because facilities are designed by system to create a whole facility that works as intended. Cost allocation is provisional because the search for designs that provide desired functionalities and subjective features such as beauty and liveability will almost certainly involve changes in the design of individual facility systems, which in turn involves moving target costs (budgets) from one innovation team to others. Designers must keep the cost of their designs within the project target cost but have flexibility to move that money across different building systems provided that target values are delivered or exceeded. To promote willingness to move money across organizational boundaries, Integrated Project Delivery1 contracts fix the percentages of profit for each company in the shared risk and reward pool based on scope allocation at the time the Target Cost is agreed. Other means for facilitating this flexibility are presented in Where did Target Value Delivery Come From? Later in this paper.

Steering is done through feedback regarding the extent to which a design adequately delivers target values within target costs. Making this happen on a Target Value Delivery project is done using Innovation Teams as the organizational unit, set-based design as the design methodology, choosing byadvantages as the decision-making methodology, and value engineering tools to regress from function to form in search of more valuable and less costly designs.

In the top row of Table 3 are the various Innovation Teams: Site/Civil, Core and Shell, etc. Team Leader, Co-Leader and Coach are named in rows 2-4, then Team Members and the Estimators supporting each Team. Individuals and the organizations that employ them are color-coded: Client- Black, Architect-Red, General Contractor-Purple, Structural Engineer-Orange, MEP Engineers-Green, Prefab Products Supplier-Yellow and Trade Partners (specialty contractors)-Black. You can see at a glance that the Teams are cross-functional.

In this example, Innovation Teams meet in all-parties events weekly or biweekly to report progress and create work plans for the following plan period. They use the Last Planner System (Ballard and Tommelein 2021) in the same way as construction crews. They produce schedules for each phase of design, they do lookahead planning to make scheduled tasks ready, they use reliable promising to populate weekly work plans with commitments, and they analyze broken promises to find and test countermeasures to prevent reoccurrence.

Once Value and Cost Targets are set, in addition to the Last Planner System and Innovation Teams, Target Value Delivery uses four other key tools: Set-Based Design, Choosing by Advantages, A3 problem solving and Value Engineering to steer Design to targets.

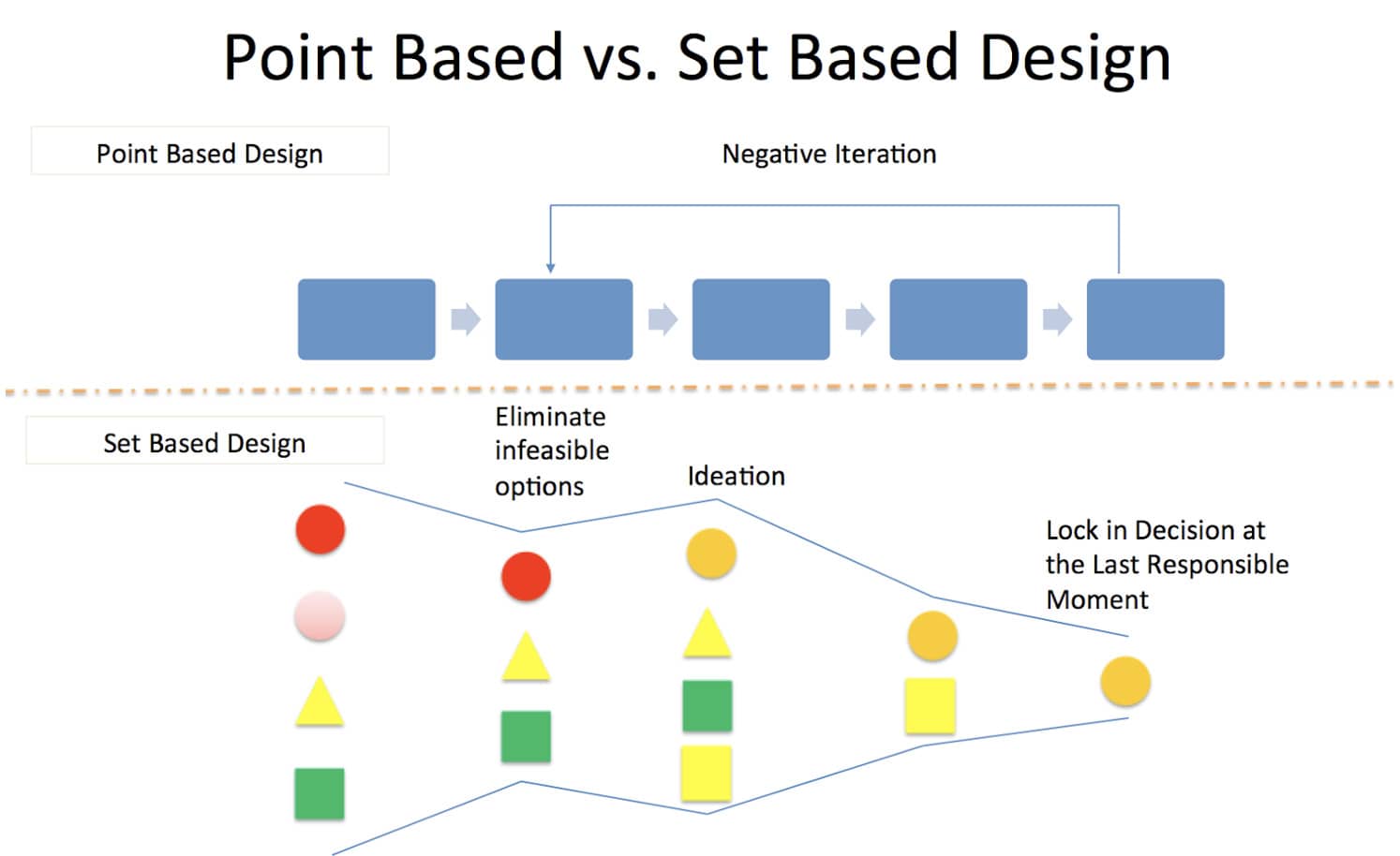

Set-Based Design is the opposite of point-based design, in which a design alternative is set early, with little or no consultation with other design disciplines and stakeholders—a method is rightly called “guessing”. Let’s suppose structural engineers have selected a design for a building structure, without consulting mechanical, electrical, building envelope, and others. There would almost certainly be problems revealed once others see the proposed solution for the structure, requiring one change after another, and perhaps even, for want of money and time, failing to deliver a building fit for purpose.

Set-Based Design has two key characteristics: 1) All decisions are made globally/after engaging all stakeholders and understanding their expectations and capabilities, and 2) Multiple alternatives are generated for each design decision before selecting the best one or, if none look able to hit both value and cost targets, designers go back to work. When known alternative designs do not deliver target value within target cost, designers invent new designs that do. It is well understood that there are no limits to generating new solutions for all types of problems other than time--but no project is without limits on time and cost. While it makes good sense to urge designers to be creative, it helps when it is known what design problems require creativity. Identifying those as early as possible is part of deciding if a project is truly viable.

The CBA process is shown in Figure 3. Alternatives are generated, factors relevant to their evaluation are agreed, criteria (requirements and preferences) are defined for each factor, and how well each alternative meets the criteria are agreed. Up to step #6, there is no evaluation of alternatives, only description. “Decide the advantages of each alternative” means agreeing that alternative A provides 30% more acoustic insulation than alternative B. First agreeing on these “attributes” has proven useful in getting consensus in evaluation of alternatives.

Evaluation begins in step 6 where the relative importance of advantages of each alternative are agreed. Typically, the most important advantage is agreed, then a range is selected (e.g., 100 pts) in which all alternatives can find a level. Cost is first considered at step #7 where the total importance of advantages of each alternative is summed up (add each one’s ranking in all the ranges), then assessed against the cost of obtaining those advantages.

Key features of CBA:

Factors represent stakeholder interests. For example, a project owner may reasonably consider capability of different suppliers as a factor in selecting them or their products.

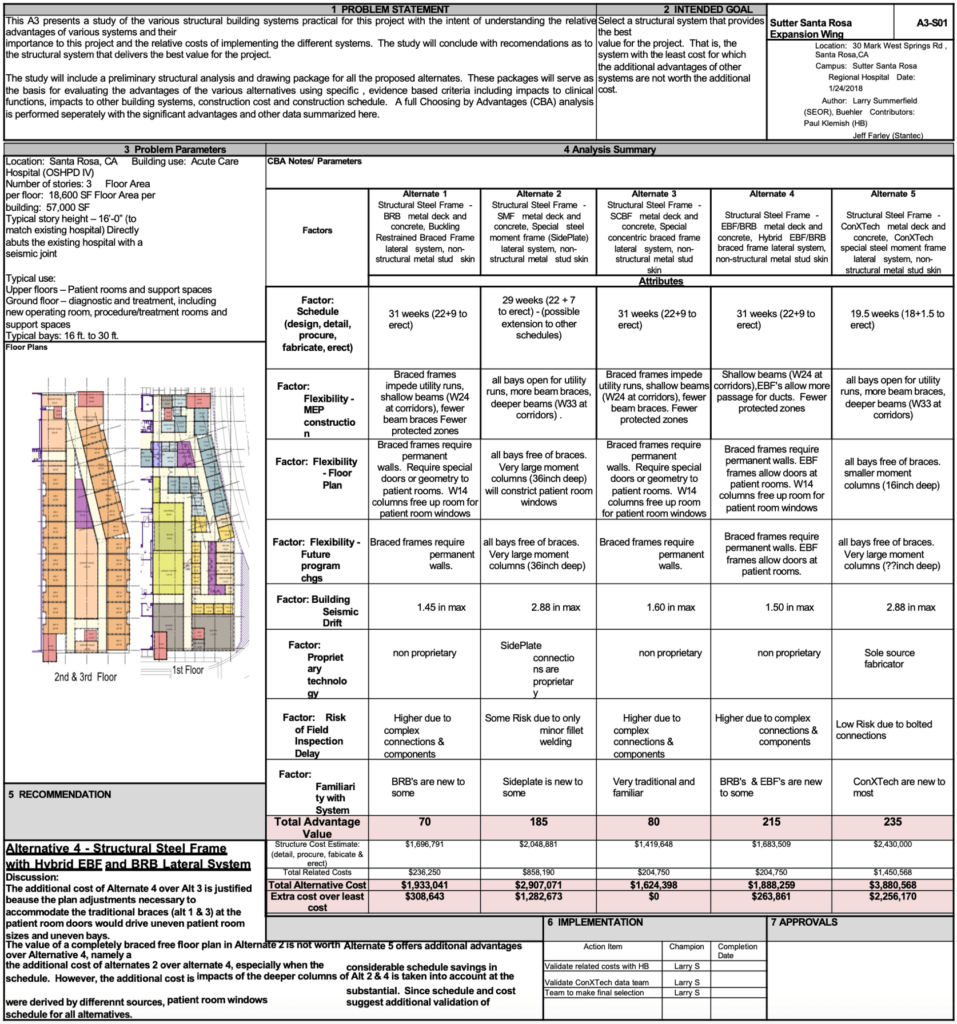

Figure 4 shows an A3 report2 with a Choosing by Advantages analysis of 5 alternative structural designs against 8 different factors. Factors include both flexibility, which is specified in terms of what changes are accommodated, and seismic drift, the maximum number of inches the building moves laterally off plumb during an earthquake. The criteria of these different factors are what alternatives are assessed against; e.g., how much seismic drift is acceptable.

In the example shown in Figure 4, the project management team accepted the proposal to develop a recommendation for a structural system by generating and evaluating alternative designs against the five factors shown in the above report. Five alternative designs were evaluated to decide on their relative advantages (value). Alternative #5 had the highest score for advantages offered at 235, with Alternative #4 in second place with 215. Because the cost for #5 was three times the cost of #4 and the additional advantage offered by #5 was only 20 out of 235 points, #4 was recommended to the Management Team.

Value Engineering is the name for various processes used to search for solutions that provide more value relative to cost. Function analysis is typical in that it involves reasoning backwards from a function to what provides or enables that function to be performed.

The four types of reasoning are [1]:

We’ve seen that regression is used to move from a functional program to a facility program for a building. If there are no answers to the question “What provides a desired function” (e.g., a desired level of acoustic insulation), abductive reasoning is used to invent and test different answers (hypotheses) until we get one that works. Regressive reasoning is also used in analyzing breakdowns such as broken promises and injuries in search of root causes and countermeasures to those causes. Abduction may come into play after all known countermeasures have been tried and found wanting or be initiated beforehand at risk of inventing a design inferior to one already invented.

Figure 5 is an example of a project on which abduction was needed to invent new ways to deliver value targets that delivered project objectives.

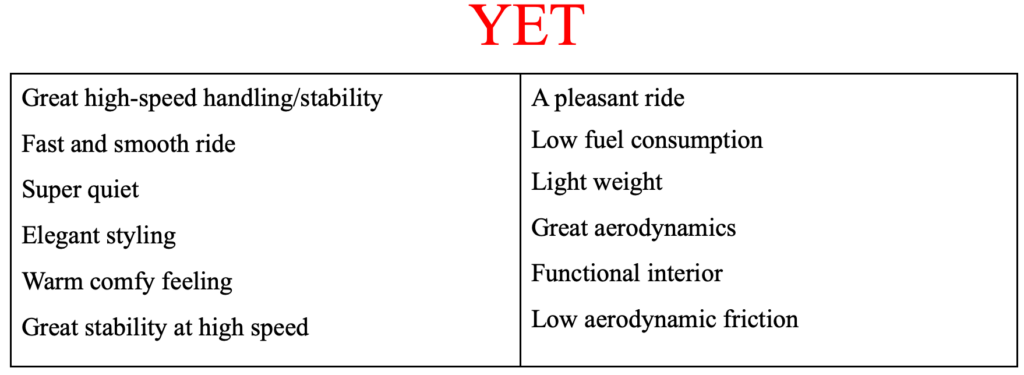

Toyota’s objective was to enter the luxury car segment of the market. The strategy was to produce a car that exceeded competitors in every dimension of performance. To operationalize that strategy, Suzuki developed his Yets; a demand that the car they designed and manufactured would have previously incompatible characteristics; e.g., great high-speed handling and stability, yet a pleasant ride. As you might expect, the criteria for the above pairs conflicted; e.g., the then accepted engineering solution for noise within the passenger compartment was to use mass to absorb vibration, but fuel consumption increases with mass and the requirement for light weight did not provide sufficient mass to deliver the requirement for “super quiet”. This conflict between noise and fuel economy was solved by redesigning engines to tighter tolerances which turned out to both reduce vibration and increase fuel economy.

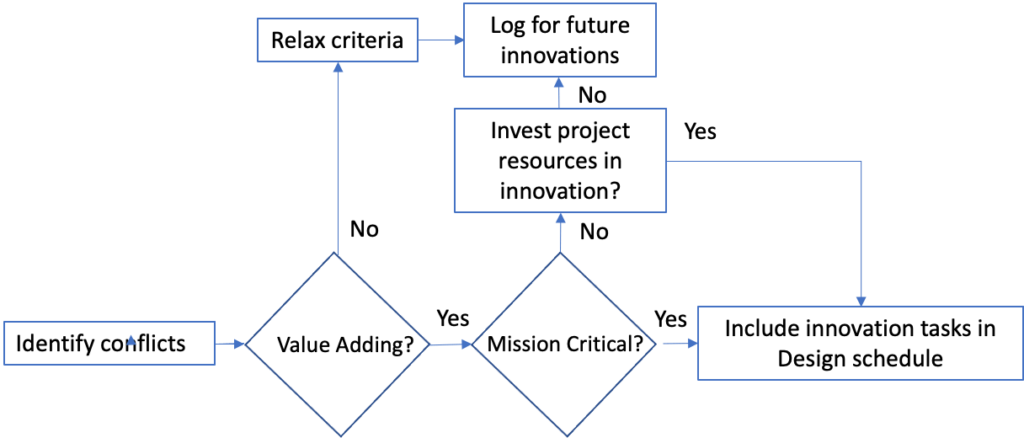

Knowing value and cost targets enables making better decisions about conflicting design criteria like those in the Lexus project. Figure 5 is a process for making decisions about conflicting design criteria. One new concept in this process is Value Targets that are Mission Critical. Some but not all projects will have one or a few objectives that must be achieved for the project to be considered successful. If that cannot be achieved, the project should be killed.

Because time is needed for abduction, we should identify in project definition where abduction is needed. The process in Figure 6 was developed for deciding what design innovations to include in a project. Delivering interior walls with a very high target sound insulation level may be mission critical for a performing arts theater, but reduction of that target may be acceptable for an office building. Where can you relax one or both conflicting must-have criteria and where must you invent new designs in which both can co-exist?

The first step in managing conflicts between design criteria is to identify them; e.g., the conflict between acceleration and fuel economy in the Lexus program. If the conflict between criteria is value adding, the next decision to make is if resolving the conflict through innovation is mission critical for the project. If it is not, it is optional if to invest in that innovation. If it is mission critical, investment in innovation is necessary or else kill the project.

Note that an innovation that resolves conflicting design criteria may not be value-adding for this client at this time but may be later and may be value-adding for other clients. Clients and construction industry designers, constructors and suppliers can contract innovation to university or other external research institutes, do it in-house off-project or within projects where feasible.

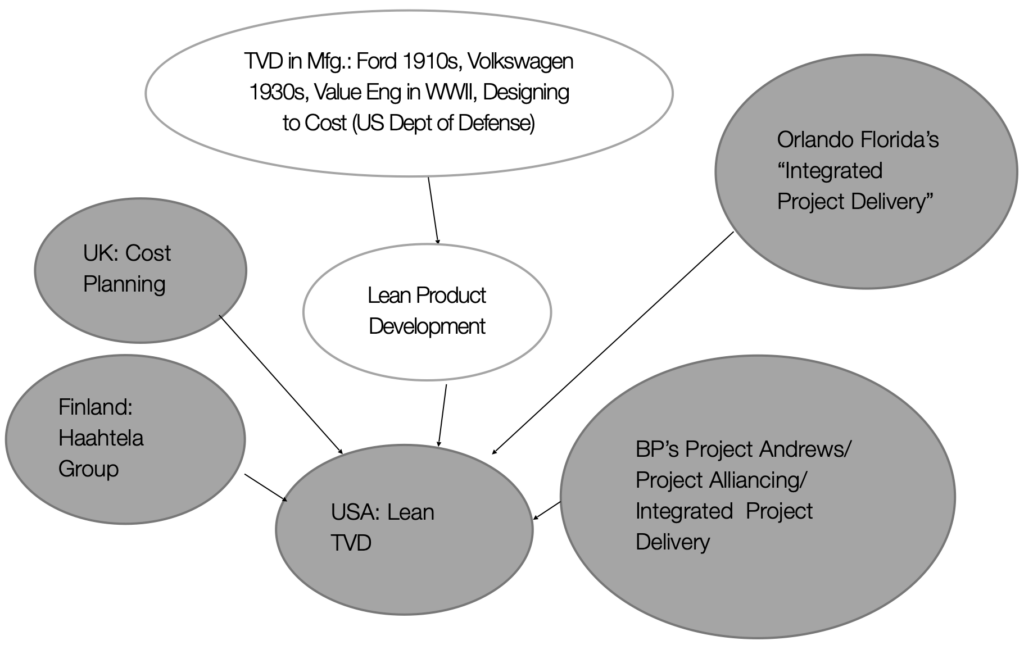

In our research, we found that TVD (not by name, but by essential features) emerged in manufacturing product development at least as far back as Henry Ford in the 1910s. It was used in Germany in the 1930s to develop the original ‘peoples’ car’ and was adopted by Toyota as its product development process in 1963. In the United States, target costing - as it was called by Toyota - was adapted for Lean Construction in 2002. I call that adaptation “Lean TVD”.

Lean TVD was influenced by four other developments, all apparently without knowledge of TVD in manufacturing. The Quantity Surveyors in the UK developed a form of TVD in the early 1950s in response to shortage of capital to invest in school construction. Finland’s Haahtela Group developed its form of TVD beginning in 1980 to provide a more rational way for the government to provide cost subsidies for construction of institutional buildings such as school and hospitals, whether private or public. In the early 1990s, British Petroleum set the target cost for Project Andrews at £373 million versus an initial estimate of £450 million. The cost at completion was £290 million and oil was produced 6 months ahead of schedule [6]. As it happens, a few years ago I was invited to advise a 30-person committee commissioned by BP to improve the way they deliver projects. We met in a telephone call, which I started by asking: “Why are you asking me what to do? You guys invented relational contracting way back with Project Andrews in the early 1990s.” A booming voice came from one of the 30 BPers on line: “What have I been telling you! We have to go back to our old way of doing things!”

BP’s TVD methodology and painshare-gainshare commercial terms made its way to Australia, where Brown and Root, the lead engineer on Project Andrews, had two successful offshore projects, then the 2000 Olympics were looming and Sydney Harbor was a cess-pool. The responsible parties left it too late to use conventional project delivery for the clean-up, so applied the BP approach using the name Project Alliancing and brought it in on time. From there more than half the public sector infrastructure projects in Australia came to be done using Project Alliancing and Integrated Project Delivery contracts were modeled in large part on Project Alliancing [7] [8].

There is one other influence on Lean IPD and it is important because it provides a different way for combining TVD with ‘relational’ contracts than either Project Alliancing or Integrated Project Delivery. Sometime around 1999, when Gregory Howell and I were managing the Lean Construction Institute, we received a telephone call from Owen Matthews, then owner/manager of Westbrook Air Conditioning in Orlando, Florida. Owen called to tell us about a company he helped form that included personnel from an Architect, Structural Engineer, Mechanical Engineer, Electrical Engineer, General Contractor, and the specialty contractors for structural, mechanical and electrical. They called this joint enterprise Integrated Project Delivery—not to be confused with the shared risk and reward contract by the same name which includes the owner. Risk and reward were shared among the participating companies, but the contracts for the project were design-construct in form.

When asked why they decided to create this new company, Owen said that being able to move budgetary funds across scopes of work was needed to make a substantial difference in project outcomes. Because the managers of each of these companies had an obligation to their own employees and shareholders to deliver as much profit as they could, if profits strictly followed work scope, no one would be willing to do more than give-and-take in ways that had small to negligible impact on profits. The companies developed a plan at the outset of projects and based profit (or loss) percentages on the work scopes in that plan. Subsequently, each companies’ cost of work was reimbursed and the remaining profit (or loss) was divided in the initial percentages [9].

We suspect that these are but a few of the TVDs to have emerged. The ones we’ve discovered have all been in response to urgent needs for radical improvement. Ford was revolutionizing the young automobile industry, Toyota was struggling to break into international markets, both Cost Planning and Haahtela’s TVD were responses to shortages of capital needed for rebuilding. BP’s Project Andrews was spurred by declining yield in North Sea oil and gas. They could not continue to do business as usual. The Egan Report [10] recommended bringing Lean principles and methods into the construction industry in response to increasing demands for construction industry performance improvement and the reported successes of Lean in manufacturing. It may be that TVD arises in conditions when doing business as usual is no longer possible.

More on TVD project performance will be available when the TVD book is published. Here are some excerpts. “The Boldt Company completed the Tostrud Fieldhouse Project at St. Olaf’s College in 2002, the first successful application of target costing to construction projects (other than in Finland)3. As noted in Ballard and Reiser (2004), Tostrud compared very favorably to another fieldhouse project done by a sister liberal arts college in the same city (Northfield, Minnesota) only two years earlier. In comparison, the cost per square foot was 2/3, the project duration was 10 months less, and St. Olaf’s Director of Facilities reported that visitors from the other liberal arts college found Tostrud to be “more beautiful and better fit for purpose”.

The Boldt Company further developed the target costing process on Thedacare’s Shawano Clinic project (Toussaint 2006), which was delivered under budget and ahead of schedule while adding additional imaging capabilities and $1 million in additional revenue to the owner. Boldt’s successes with TVD encouraged Sutter Health to try target costing in 2006 on their Fairfield Medical Office Building, which was delivered 5.2% below target cost and 18% below market.

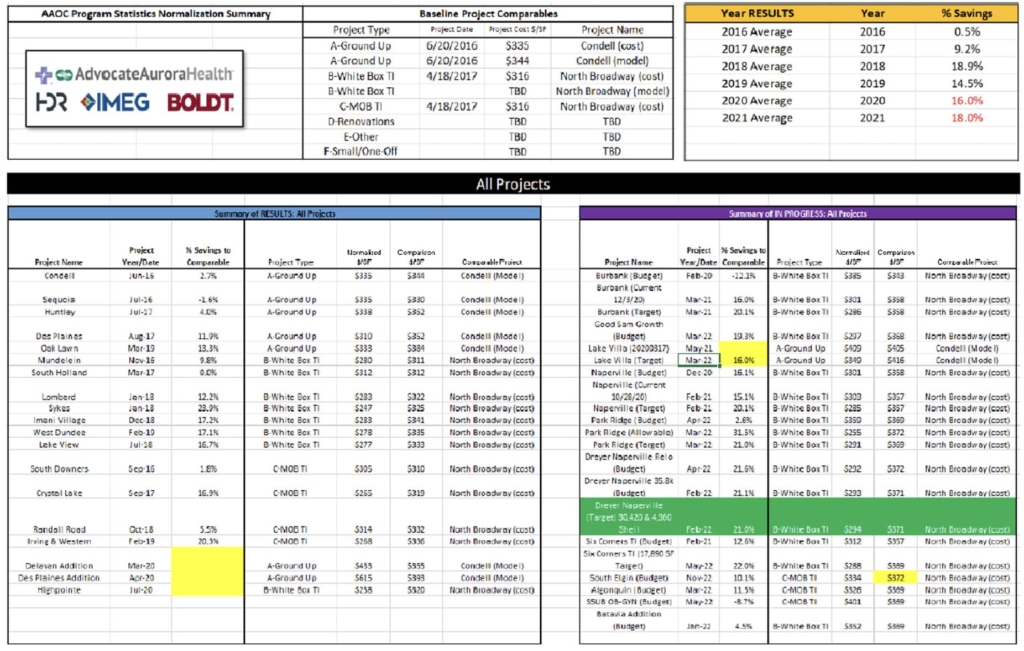

Table 4 is a project report provided by HDR Architecture and Engineering in Chapter 7.2 of the book TVD in Building Projects. This figure describes the cost outcomes of that multi-year program for designing and delivering various types of out-patient facilities for Advocate Aurora Health in the United States. Measured program-level cost savings year to year were: 2016-0.5%, 2017-9.2%, 2018- 18.9%, 2019-14.5%. Estimated cost savings for 2020 and 2021 were forecast and later confirmed at 16% and 18%.

This is a summary report on how the program has performed thus far:

TOTAL: $17,719,459 cost savings (12.16%).

There have been many published reports on how TVD projects perform, e.g., [l4], [15], [16] and [17], many of them focused on projects with shared pain-gain commercial terms4. We can, of course, evaluate TVD based on common sense principles and we’ve seen how British Petroleum’s Project Andrews and others have performed against cost and time targets. There are many publications reporting on the performance of TVD projects, but to my knowledge, there have been no comprehensive analyses, perhaps in part because there are different understandings of TVD and the elements that help make it work. Hopefully this paper and the TVD book will help reduce those differences.

Target Value Delivery can be used with any form of project contract that allows designers and constructors to work together in the design phase of projects. That minimum requirement is provided by all forms of contract other than design-bid-build. It is also provided by owners engaging companies that can provide most or all of the design and construction expertise needed in a project. Owners can also award contracts to preferred suppliers conditional upon performance, thereby providing those suppliers the potential to recover losses on future projects. Alternatively, owners could contract with construction managers who have preferred suppliers. Traditional negative and positive incentives have also been shown to work, e.g., in the University of California San Francisco’s non-medical facilities program [11].

All these different ways to promote intense collaboration are but starting points to creating a learning culture. Linking profit to outcomes may persuade the owners of the various businesses involved in a project to give their employees permission to collaborate, but how the project and its people are organized and managed is needed to take advantage of that permission.

To my knowledge, no research has been published on the relative merits of the different ways of securing the minimum contractual requirement for TVD projects. Should that research be done in the future, it should take into account the relative complexity and uncertainty of the project. The more projects increase in complexity and uncertainty, the more innovation is needed in both product and process design, and hence also more intense collaboration.

Target Value Delivery is a powerful method for setting and steering projects to value and cost targets. How that is done has been explained in this paper, including descriptions of the key methods used: innovation teams, set-based design, A3 reports, Choosing by Advantages and value engineering. The paper also provided an overview of the historical development of TVD and addressed its’ relationship with forms of collaborative contracts such as Project Alliancing and Integrated Project Delivery, which may be the more needed for complex and uncertain projects, but additional research is needed to determine how best to promote collaboration in different circumstances.

As the name suggests, Target Value Delivery of Building Projects describes TVD in building projects, but process and infrastructure industries have played key roles in its development. Research, both practical and academic, is needed to create the evidence to be presented in a future book titled Target Value Delivery of Projects.

1 On Integrated Project Delivery and Project Alliancing projects, owners and key design and construction service providers share project risk and reward.

2 A3 reports, limited to what fits on an A3 sheet of paper, are used for problem solving in Lean Product Development and have been adopted in TVD. There are standard parts of the report, starting with a Problem Statement and ending with a Recommendation, followed by Implementation tracking and Approvals. A3s that have been approved or are otherwise valuable are archived for future use.

3 Nicolini et al. (2000) reported a failed attempt by the U.K. Ministry of Defense.

4 These reports have been for the most part positive but see [12] and [13] for cautions.