The stage gate project development approach1, as adopted by the engineering and construction industry, was designed as a business process both to meter spending prior to the investment decision and yield predictable outcomes. It has been widely implemented across industrial capital project sectors such as energy, mining, infrastructure, chemicals and pharma. While it can deliver on its intent, if applied too rigidly, it also drives deleterious, unintended consequences that increase cost, lengthen schedules and erode returns on capital employed.

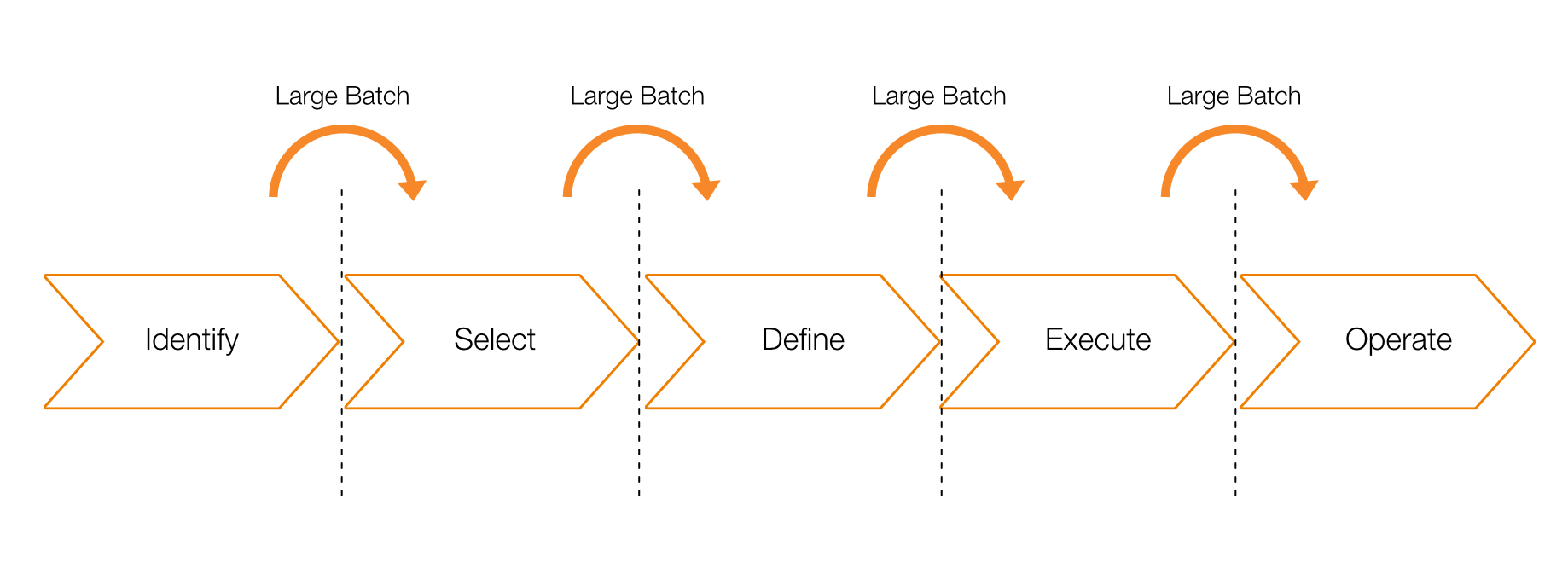

As a business process, the inflexible stage gate approach does not support the needs of project development and execution. Instead, it subordinates the project to the business process and suboptimizes performance. All too often, the project team focuses merely on passing the next stage gate as opposed to keeping the end in mind. Consequently, efficiencies that would result from more laminar development and execution are lost and exceptionally large batches of work accumulate at the stage gate by design. According to the laws of Operations Science, such accumulations of work-in-process necessarily lengthen cycle time and increase costs.

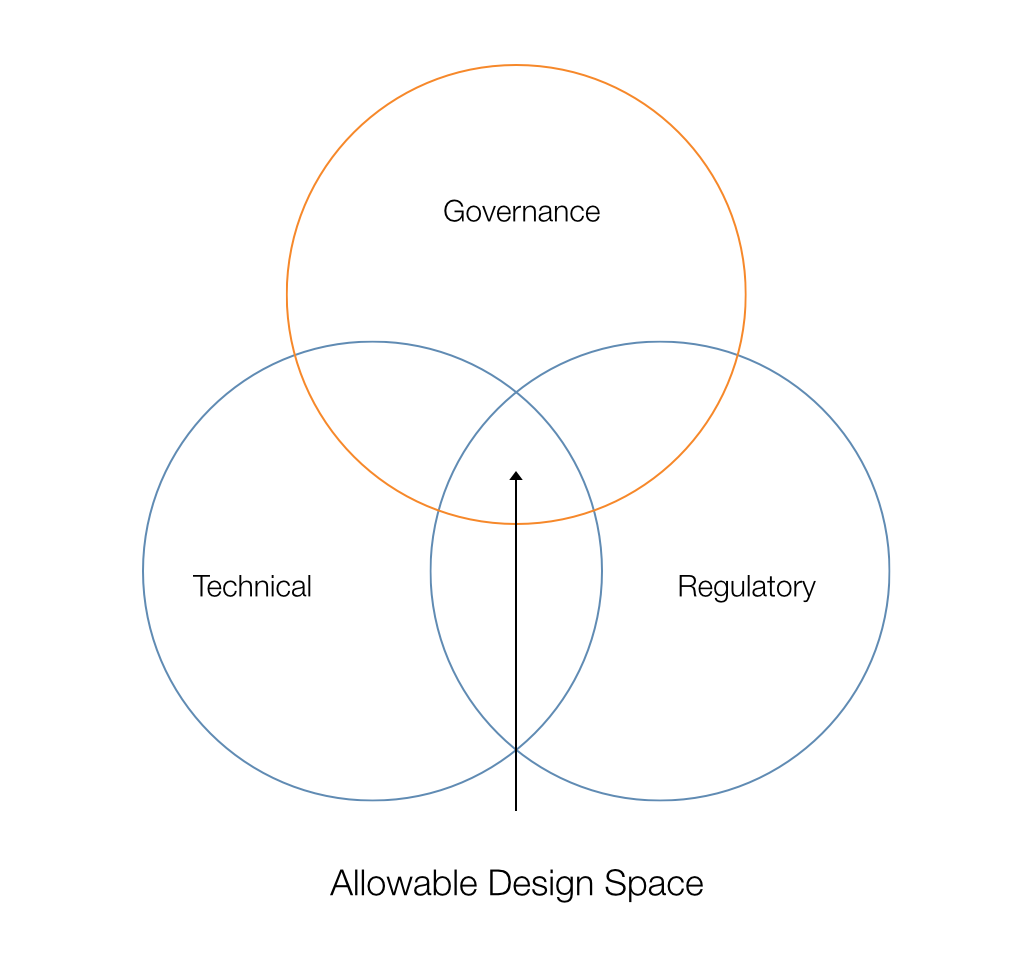

Considering the laws of Operations Science, a better approach is to adapt the business process to the needs of the project after taking into consideration other driving forces of technical, regulatory and governance requirements which form the design space for any investment. The business investment decision should be triggered by a defined set of prerequisites or conditions precedent, the timing of which varies depending on the nature of the project. For example, a complex brownfield project would need to advance definition comparatively more before making the investment decision than an otherwise straightforward greenfield effort.

In addition, looking down the road with the advancement of computing technology, the project process will radically change and improve. Using concurrent digital engineering, thousands of alternatives will be considered to optimize the desired outcome. The chosen alternative will come with a nearly complete design, cost estimate and production schedule. This will make stage gate, as the industry knows it today, virtually obsolete, which will enable reliable investment decisions to be made at the point of concept select with minimal pre-investment. Some companies recognize the inherent weakness of stage gate and have already moved the investment decision to concept select while using current, unreliable methods.

Variants of the stage gate approach likely existed when Pharaoh built the pyramids, but the modern instances arose in the 1940s in large-scale mechanical and chemical engineering projects. In 1958, recognizing the growing adoption of the process, the American Association of Cost Engineers defined four types of cost estimates roughly correlated with the stages. Although their definitions have since evolved, they remain roughly consistent today. During the 1960s, NASA integrated a phase review process that consisted of five stages with a required review at the end of each stage. As such, it was arguably the first generation of a governance process that presaged the stage gate processes we see today. Capitalizing on NASA’s success in managing innovation with the process, Robert Cooper published Winning at New Products in 1986, which trademarked the Stage-Gate System®. Cooper’s application was targeted to create a repeatable process for development of new products, not for capital projects that metered the spend “never betting all the money until you are ready to launch.” He advocated for managing rather than mitigating risk by balancing the portfolio with multiple new products with different risk profiles using these three key principles:

By the end of the 1980s, Exxon Chemical and DuPont, who were both developing new products, adapted the stage gate approach as a development and governance framework for capital projects. They sought to meter the spend and make the investment decision before significant financial commitments were made. In their adaptation, however, they failed to incorporate Cooper’s three key principles. In fact, stage gate applied to capital project development and execution cannot incorporate the principles.

Years after introducing the concepts, Cooper observed and warned that unless managed carefully with the three principles in mind, the stage gate process often becomes cumbersome, bureaucratic, painful to navigate and rigid, which stifles or stops innovation. It should be noted that even Cooper’s approach has evolved to one employing agile principles called “Agile-Stage-Gate®, the Next Generation Idea-to-Launch Process.”

At its core, stage gate is a standardized method to assess the viability of an opportunity, explore alternatives, select a concept and then execute the project. Investment in developing an opportunity is metered in the early phases, allowing the final investment decision (FID) to occur prior to substantial financial commitments. It also helps manage the transition from what is a heavy business focus in the early stages to a technical focus and then a project execution focus in Phase 4. Key elements of each stage or phase are summarized below:

Stage / Phase 1 – Identify a business need or opportunity. This can arise from a regulatory mandate to a potential acquisition of a business that requires capital investment. A key element of Stage 1 is to clearly define the opportunity the business is pursuing or what problem the business is trying to solve. This frame focuses all subsequent activities accordingly.

Stage / Phase 2 – Develop and consider alternatives that can exploit the business opportunity or satisfy the business need. This stage culminates in the selection of a concept, or business decision to continue or halt investment in the opportunity.

Stage / Phase 3 – Define the selected opportunity with sufficient engineering and execution planning to enable predictable estimates of cost, schedule and business outcomes. (This stage is commonly known as FEED in the energy sector.) This stage culminates in the Final Investment Decision.

Stage / Phase 4 – Execute engineering, procurement, transportation, fabrication, construction and completion/testing activities of all facilities. This stage culminates in the transfer of custody and control to the operating organization.

Stage / Phase 5 – Operate the asset. While this phase could be interpreted as representing the operational life of the asset, practically, it is only hand over to and acceptance of the facilities by the operating organization. Undoubtedly during the asset life cycle, there will be many new projects to debottleneck, expand, upgrade or renew the facilities, each with their own stage gate work process.

On the surface, stage gate appears to be a very logical approach to minimize pre-investment in maturing an opportunity and generating predictable business outcomes. Critical to the model is an underlying belief that any project can be divided into parts or stages, and if each part or stage is optimized, the sum of those parts yields a greater whole.

After nearly four decades of experience with stage gate it is fair to ask – does it work? Before addressing that question, let’s dig a little deeper into what is happening.

Setting stage gate aside for a moment, let’s examine the underlying work that must be done. The table below summarizes the fundamental phases of project work along with the current approach. It should be noted that in reality, each subsequent phase completes the predecessor phase. (Even in stage gate, the handoff between stages is not that clean. Ideally, each stage is completed before moving to the next stage; however, in reality, considerable overlap between phases occurs. The gates are quite porous, and the passed baton is often fumbled.)

This means that design completes define, while construct completes design. For example, in design we often discover conflicting requirements or insufficient details, both of which require resolution. Design conflicts and scope that cannot be constructed are regularly discovered in construction and require field engineering to resolve. We could even say that operation completes construction with discovery in start up to correct construction deficiencies.

| OPPORTUNITY SHAPING | DEFINE | DESIGN | CONSTRUCT | |

|---|---|---|---|---|

| Purpose | Assess business opportunity | Establish requirements for design | Create technical basis and provide materials to construct and operate | Construct asset that meets design intent |

| Objectives | Select concept (or stop) | Finalize regulatory, technical and business requirements | Synchronize design and purchasing to support construct and start up needs. | Efficiently transform materials into operating asset |

| Processes | Commercial evaluations, market analysis, subsurface evaluations, alternative analysis | Identify requirements

Critical path scheduling Contracting and procurement strategy formulation Project execution planning |

FEED and detailed design

Procurement of equipment and materials Transporting equipment and materials to the job site

|

Fabricate,

Deliver / Transport Assemble, Install, Commission |

| Deliverables | Frame, concept, economics, commercial agreements | Basis of Design

Project Execution Plan Cost and Schedule |

Digital Assets

Equipment and materials |

Asset operating in accordance with requirements |

Across all these phases of work, there are different streams with significantly different levels of immutability or ability to influence. These are described in the table below from the least ability to influence to the greatest. These streams of work must be factored into the development plan of any capital project as they impose requirements that dictate the sequence of work and in some cases such as regulatory concerns, the timing as well.

It is vital that the interdependencies be considered in the rate of definition and development of the individual streams. For example, it is all too easy to advance technical progress well ahead of commercial agreements. Doing so places all the technical work at risk and significantly diminishes commercial agreement negotiating leverage.

| TYPE | SOURCE | INFLUENCE |

| Technical | Driven by science – subsurface data, facilities design basis, location, environment and required startup sequence. | Immutable – science-based and cannot be changed. Technical work must be done in a specific sequence. There must be sufficient quality of information in sequence to perform the work. |

| Regulatory | Requirements imposed by regulators, codes and standards. | Early in development, some requirements can be negotiated to be more favorable. However, in the Define stage they become firm. |

| Governance | Requirements imposed by commercial agreements and production sharing agreements. Decision-making framework or partner framework, work processes, contracting strategy, funding approvals, stakeholder management plans. | Once established, requirements arising from commercial agreements are very difficult or impossible to change. Internal framework can be changed to match project needs. External frameworks can sometimes be influenced to match project needs. |

Understanding this provides a hint at why the current stage gate approach is not working. These three streams of work form the design space for any project. Specifically, only concepts that satisfy the demands or needs of each simultaneously should be considered viable.

After four decades of industry experience with stage gate, capital project performance continues to be largely unpredictable.2 Despite the investment in Stages 1-3 and a concerted focus on achieving greater levels of definition and execution planning, projects frequently take much longer and cost considerably more than estimated. The value erosion from these outcomes easily tallies in the billions every year. So, while laudable in the goal, the objective analysis would conclude it is not working.

Why not?

Stage gate is a business decision making and governance framework that overlays the actual work that must be done to create a capital project asset. Contrary to Cooper’s principles and in accord with his admonishment, it has evolved as a rigid and inflexible approach which makes it difficult or impossible to cope with the variability that inherently resides within all projects. Among the many sources of variability that surface on projects, changing expectations/requirements of regulators, partners and other key stakeholders stand among the more prominent. All too often, the collective goal is seen myopically as completing only the work necessary to pass through the next gate and not what would make the overall investment successful. This has two profound effects on the project:

Not all projects are the same. Consequently, rigid stage gates suboptimize how work gets done. Some are straightforward and could secure FID at concept select. Others require nearly all the engineering to be complete to develop a reliable bill of materials, secure funding and obtain necessary permits.

Work accumulates in large batches at each gate which means by definition projects take longer and cost more than what is possible.

Other issues observed include:

Before stage gate, there was chaos in the approach to project development and execution. Stage gate tamed the chaos using a large batch approach meaning very large chunks of work done to move through successive gates as seen in the figure below. While chaos was reduced, stage gate created many unintended consequences that plague the bottom line with unpredictable outcomes, longer cycle times and increased cost.

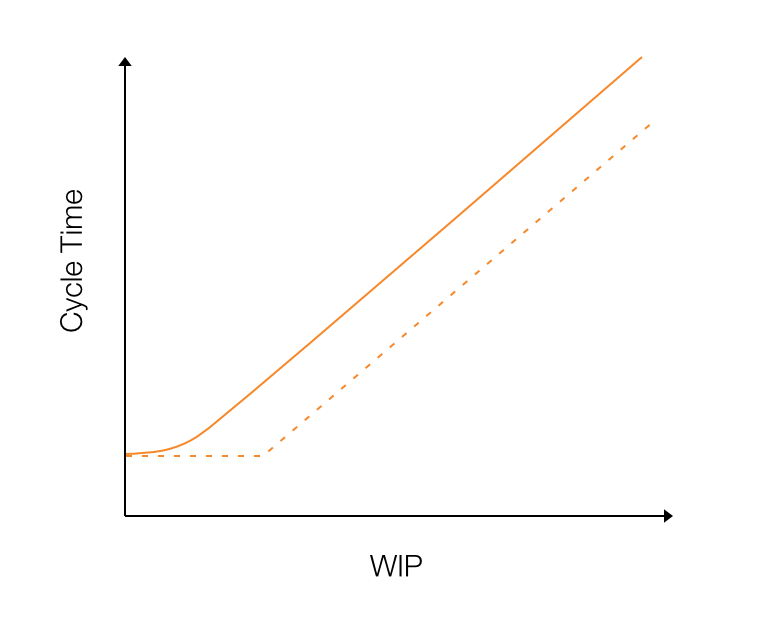

Operations Science (OS) governs all production systems. Capital projects are production systems, transforming ideas and raw materials into facilities to meet a business opportunity. Operations Science is always at work, even if not understood or recognized by those involved. This science explains why projects currently suffer poor results with stage gate. For example, a key OS equation is Little’s Law which states:

Cycle Time = Work in Process / Throughput

Graphically the relationship looks like this:

The large batches of work done to move through each gate are nothing more than Work in Process (WIP). Using Little’s Law, these large batches of Work in Process necessarily translate to longer cycle times.

As the next logical evolution in project development and execution, we propose moving beyond stage gate batch process to a Continuous Flow approach. It will still tame the chaos but rid the industry of the negative unintended consequences that came with stage gate, satisfy the business decision-making need while optimizing the cost and cycle time of the investment, and adhere to the three key principles identified by Cooper.

Principles of this Continuous Flow approach are fundamentally different than current systems:

This mapping must also clearly identify the business drivers. For example, in the energy sector, the driver is typically return on investment, for health care it is driven by the need to provide health care to a growing population and for data centers driven by expansion of cloud computing and 5G networks.

This mapping must also clearly identify the business drivers. For example, in the energy sector, the driver is typically return on investment, for health care it is driven by the need to provide health care to a growing population and for data centers driven by expansion of cloud computing and 5G networks.

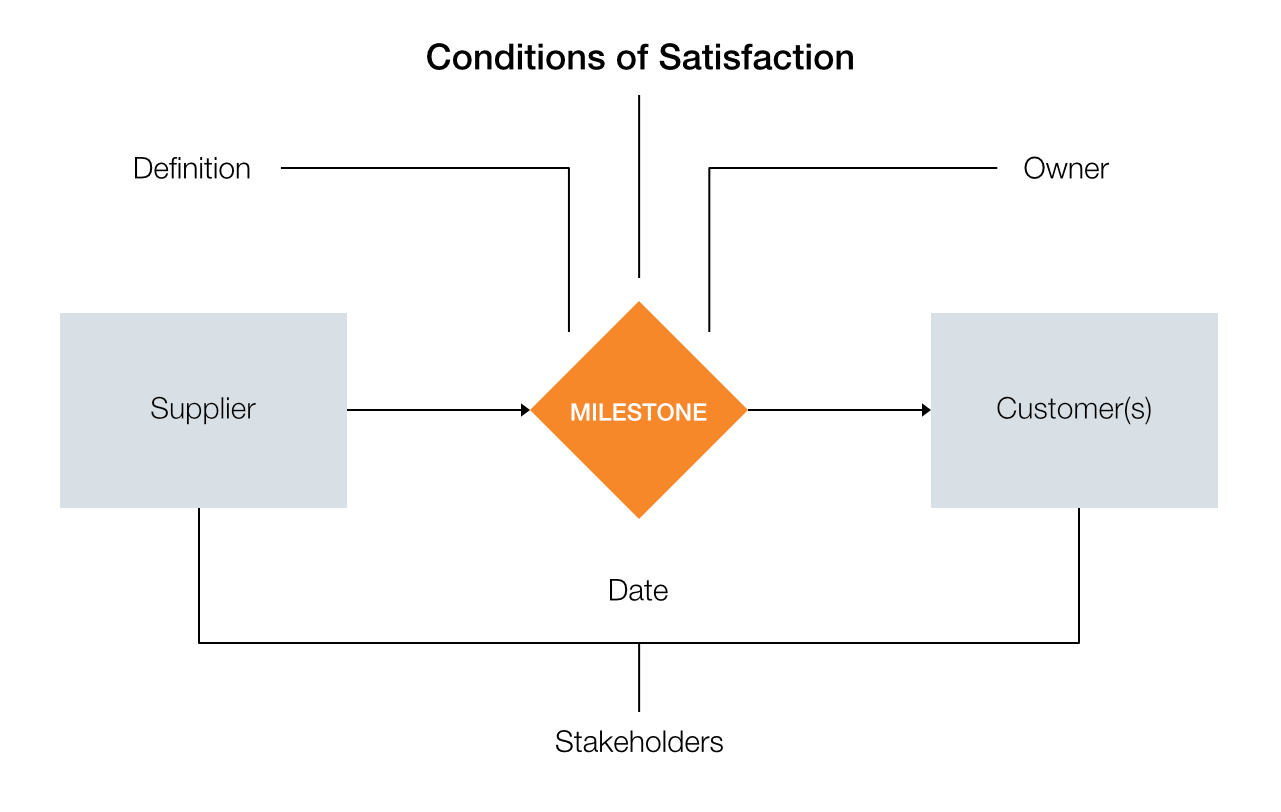

| ITEM | MILESTONE DESCRIPTION |

| Scope | A very vivid narrative of what needs to be accomplished including description of deliverables and outputs |

| Conditions of Satisfaction | A very vivid description of the customer/supplier agreement upon which to execute, deliver and measure acceptance for a specific scope of work |

| Stakeholders | The stakeholders who can affect or are affected by the work |

| Process | How the milestone will be accomplished |

| Location | Where the milestone will be accomplished |

| Responsible | Who will be responsible for getting the milestone accomplished |

| When | Date when the milestone needs to be accomplished |

Each milestone must be carefully defined with a clear set of required deliverables. It should be left to the downstream party to determine whether the milestone has been achieved before declaring success.

In addition, because a project is an amalgamation of many individual production systems, they can easily be reused on successive projects. An organization that leverages the standard work processes for individual production systems essentially institutionalizes them in a “library” available to all projects which can then be improved over time.

Significant differences in the way work is done through the lifecycle of the project by implementing these principles is shown in the table below.

| OPPORTUNITY SHAPING | DEFINE | DESIGN | CONSTRUCT | |

| Purpose | Assess business opportunity | Establish requirements for design | Create technical basis and provide materials to construct and operate | Construct asset that meets design intent |

| Objectives | Select concept (or stop) | Finalize regulatory, technical and business requirements | Synchronize design and purchasing to support construct and start up needs. | Efficiently transform materials into operating asset |

| Processes | Mapping of the allowable design space / identification of constraints

Commercial evaluations, Market analysis, subsurface evaluations, alternative analysis Start with the end in mind Develop work sequence before developing schedules and setting dates Test alternatives to ensure that they are optimized for the eventual production system in project delivery

|

Identify requirements

Map and model milestones Production system design Contracting and procurement strategy formulation supporting the project production system |

Design Process

Concurrent Engineering Manufacture Deliver / Transport Design the workflows – Start by understanding how we do work, from the people doing the work Synchronize the design, supply chain & construction workflows & plans Collaborate and integrate – Transparently, understand and integrate with the production systems for selected suppliers Synchronize project system are networks that pull on supply chains with execution |

Fabricate,

Deliver / Transport Assemble, Install, Commission Design Workflows with operation science and condition-based progression to ensure work is completed in sequence Embed Operations science policies into Workflows and standard processes for executing work

|

| Digital & Data | Harness data to enhance forecasting, enable continuous improvement and inform decisions, while aiding future projects

Work breakdown structure and the 3D model are designed with the end in mind to serve the diverse needs of the project team through its lifecycle. |

|||

| Deliverables | Frame, concept, economics, commercial agreements | Basis of Design, Basis of Process (how the work will be done), policies that control the work | Digital Assets

Equipment and materials |

Asset operating in accordance with requirements |

Throughout the life cycle of the project, each part is synchronized through the project production system design and schedule. The sequence of work is derived working back from startup, commissioning, construction, procurement and then design. Long lead materials, bulk construction, large hand-offs between contractors become a thing of the past. The focus is not to optimize each phase or sub-portion of a project but to optimize the whole.

Underlying beliefs and both mental and business models are at play. Consequently, significant effort will be required to unlearn years of habits and realize the point where project leaders and teams are fluent in OS/PPM and its application in day-to-day decision making and methods.

Contractors face an even more imposing challenge, because they are heavily invested in the status quo and may not have a financial motivation to change. Arguably, given the current contracting models, some may even harbor dis-incentives to change. Owners must create that motivation and engage contractors who want to do business in this new way collaboratively.

Looking down the road in the not-too-distant future, technology advancement will enable digital concurrent engineering during opportunity shaping (concept select) coupled with data analytics to shorten development time significantly and improve quality on projects. During concept select, advanced designs will be generated in days as opposed to months. Moreover, reliable bills of material, estimated costs and a production schedule will accompany each alternative considered. This will enable the business to judge early on the viability of each concept and determine if the investment should be made. From that point on, the project will flow with the most efficient project production plan and unconstrained by rigid business processes.

As engineering becomes automated and integrated with suppliers’ systems, the cycle time for the design phase will also be significantly reduced. On very large projects, what takes 2-4 years now will likely be done in a matter of months.

All of these advancements reinforce the need to move away from an inflexible stage gate approach to an agile business process that supports project development and execution efficiency.